FEM tutorial: Difference between revisions

m (Resized image) |

(Marked this version for translation) |

||

| (51 intermediate revisions by 14 users not shown) | |||

| Line 1: | Line 1: | ||

<languages/> |

|||

<translate> |

<translate> |

||

<!--T:1--> |

<!--T:1--> |

||

{{TutorialInfo |

{{TutorialInfo |

||

|Topic= |

|Topic=Finite Element Analysis |

||

|Level= |

|Level=Beginner |

||

|Time= |

|Time=10 minutes + Solver time |

||

|Author=[http://freecadweb.org/wiki/index.php?title=User:Drei Drei] |

|Author=[http://freecadweb.org/wiki/index.php?title=User:Drei Drei] |

||

|FCVersion=0. |

|FCVersion=0.17 or above |

||

|Files= |

|||

}} |

}} |

||

== Introduction == <!--T:29--> |

|||

! DO NOT TRANSLATE AT THE MOMENT ! work in progress ! see [[FEM_CalculiX_Cantilever_3D]] too. |

|||

<!--T:8--> |

|||

This tutorial is meant to introduce the reader to the basic workflow of the FEM |

This tutorial is meant to introduce the reader to the basic workflow of the FEM Workbench, as well as most of the tools that are available to perform a static analysis. |

||

</translate> |

|||

<!--T:9--> |

|||

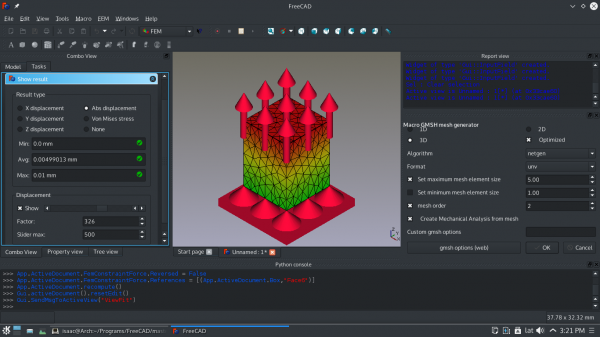

[[Image:FEM_tutorial_result.png| |

[[Image:FEM_tutorial_result.png|600px]] |

||

<translate> |

|||

== Requirements == <!--T:30--> |

|||

* For working with FreeCADs [[FEM_Module]] it is '''STONGLY''' recommended to use version 0.16 or above. |

|||

* The use of FreeCADs [[FEM_Module]] requires the installation of some external software. Check [[FEM_Install]] for further install instructions. |

|||

* The reader has the basic knowledge to use the Part and PartDesign Workbenches |

|||

<!--T:10--> |

|||

* FreeCAD version 0.17 or above. |

|||

* [http://sourceforge.net/projects/netgen-mesher/ Netgen] and/or [http://geuz.org/gmsh/ GMSH] is installed on the system (included in the FreeCAD installation). |

|||

* [http://www.calculix.de/ Calculix] is installed on the system (included in the FreeCAD installation). |

|||

* The reader has the basic knowledge to use the [[Part_Workbench|Part]] and [[PartDesign_Workbench|PartDesign]] Workbenches. |

|||

== Procedure == <!--T:2--> |

|||

=== |

=== Modeling === <!--T:31--> |

||

<!--T:11--> |

|||

In this example a Cube is used as the study object, but |

In this example a Cube is used as the study object, but any model created in the Part or PartDesign Workbenches can be used instead. |

||

<!--T:12--> |

<!--T:12--> |

||

# Press the {{Button|[[Image:Std_New.svg|16px|link=Std_New]] [[Std_New|Std New]]}} button to create a new document. |

|||

# Create a new document |

|||

# Activate the Part Workbench |

# Activate the [[Image:Workbench_Part.svg|24px|link=Part_Workbench]] [[Part_Workbench|Part Workbench]]. |

||

# Create a Cube |

# Create a Cube. |

||

# Change its '''Dimensions''' to the following: |

|||

# We have a geometrical model to work with right now. |

|||

## Length: 8.000 m. |

|||

## Width: 1.000 m. |

|||

## Height: 1.000 m. |

|||

<!--T:13--> |

|||

Now we have a model to work with. |

|||

=== Creating the Analysis === <!--T:32--> |

|||

<!--T:41--> |

|||

==== Create an analysis and mesh the geometrical model ==== <!--T:13--> |

|||

# Activate the [[Image:Workbench_FEM.svg|24px|link=FEM_Workbench]] [[FEM_Workbench|FEM Workbench]]. |

|||

# Switch to the FEM Workbench |

|||

# Select the {{MenuCommand|Model → [[Image:FEM_Analysis.svg|16px]] Analysis container}} option from the menu. |

|||

# Do '''NOT''' select any object neither in tree view nor in model space |

|||

# Click [[Image:Fem_Analysis.svg|32px]] [[FEM Analysis|New mechanical analysis]] to create a analysis. |

|||

# An analysis container and a solver object will be created. |

|||

# The analysis should be activated already. |

|||

# If a file is reloaded the analysis has to be activated before anything could be done with the analysis objects. To activate an analysi make a right click in tree view on the analysis and activate the analysis. |

|||

=== Constraints and Forces === <!--T:35--> |

|||

# Next step will be to give an material to our model |

|||

# Select [[Image:Fem_Material.svg|32px]] [[FEM Material|Mechanical material...]] and choose Steel-generic as the material |

|||

# Click '''OK''' |

|||

<!--T:19--> |

|||

# Hide the mesh from the Tree View. |

|||

# Show the original model. |

|||

# Select [[Image:FEM_ConstraintFixed.svg|24px|link=FEM_ConstraintFixed]] [[FEM_ConstraintFixed|Create FEM fixed constraint]]. |

|||

# Click {{Button|Add}}, select the back face of the Cube object (face on the '''YZ''' axis) and click {{Button|OK}}. |

|||

# Select [[Image:FEM_ConstraintForce.svg|24px|link=FEM_ConstraintForce]] [[FEM_ConstraintForce|Create FEM force constraint]]. |

|||

# Click {{Button|Add}}, select the front face of the Cube object (the face parallel to the back face) and set the '''Force [N]''' value to 9000000. |

|||

# Set the '''Direction''' to '''-Z''' by selecting one of the face edges parallel to that direction. |

|||

# Click {{Button|OK}}. |

|||

<!--T:20--> |

|||

We now have established the restrictions and forces for our static study. |

|||

=== Material === <!--T:42--> |

|||

# What needed next is to add some fixed and force constraints to our model. |

|||

# Select [[Image:Fem_ConstraintFixed.svg|32px]] [[FEM FixedConstraint|Create FEM fixed constraint]] |

|||

# Select the bottom face of the Box and click OK |

|||

# Select [[Image:Fem_ConstraintForce.svg|32px]] [[FEM ForceConstraint|Create FEM force constraint]] |

|||

# Click on Add Reference button in task panel of force constraint. |

|||

# Select the top face of the Box and set the '''Area load''' value to 20 000 N. |

|||

# The unit is fix and will be in Newton. The force is distributed on all given references. |

|||

# Click OK |

|||

# We now have established the restrictions and forces for our static study. What is missing is the FEM Mesh. |

|||

<!--T:21--> |

|||

# Select [[Image:FEM_MaterialSolid.svg|24px]] [[FEM_MaterialSolid|Material for solid]] and choose Calculix-Steel as the material. |

|||

# The two possibilities by either the build in mesher Netgen and the external mesher GMSH will be shown in this tutorial. There are various possibilities to get an valid FEM Mesh. See [[FEM_Mesh]] if you are interested in more detailed descriptions. |

|||

# Click {{Button|OK}}. |

|||

=== Meshing === <!--T:43--> |

|||

# Select the shape you wish to mesh, in this case our Cube and click on [[Image:Fem_FemMesh.svg|32px]] [[FEM Create|Create FEM mesh]]. |

|||

# If you did not change the size of the cube geometry (standard is 10 mm x 10 mm x 10 mm) you can leave the settings and click ok. |

|||

# The mesh will be created. |

|||

# The properties of the FEM mesh can be seen in the property editor of FreeCAD. |

|||

# Drag the FEM mesh object inside the Analyis. |

|||

<!--T:44--> |

|||

It is recommended to make a mesh as the last step in the analysis preparations due to association to a geometry in FreeCAD. |

|||

# If FreeCADs build in mesher Netgen is not available the usage of [[Macro_GMSH]] is recommended, and is used for this example. |

|||

Depending on FreeCAD installation, there can be Netgen or GMSH meshers, you can use any of them. |

|||

# Start the GMSH macro |

|||

# Select the shape you wish to mesh, in this case our Cube |

|||

# Since we have an analysis object already make sure the box '''Create Mechanical Analysis from mesh''' is not activated. |

|||

# Click '''OK''' |

|||

# The FEM mesh object will be created. |

|||

# Drag the FEM mesh object inside the Analyis. |

|||

==== |

==== Netgen ==== <!--T:33--> |

||

# Select the solver object [[Image:Fem_Solver.svg|32px]] of the analysis in tree view and press [[Image:Fem_QuickAnalysis.svg|32px]] [[FEM_RunCalculiXccx|Quick Analysis]] from the icon tool bar |

|||

# The analysis will be made and the result object should be created. |

|||

<!--T:15--> |

|||

# Select the model. |

|||

# Select [[Image:Fem_Result.svg|32px]] [[FEM ShowResult|Show result]] |

|||

# [[Image:FEM_MeshNetgenFromShape.svg|24px]] [[FEM_MeshNetgenFromShape|FEM mesh from shape by Netgen]]: Generates a finite element mesh for a model using Netgen. |

|||

# Choose among the different Result types to view the results |

|||

# In the meshing dialog, click {{Button|Apply}} and {{Button|OK}}. |

|||

# The slider at the bottom can be used to alter the mesh to view the deformation in a simplified manner |

|||

#To remove the results select [[Image:Fem_PurgeResults.png|32px]] [[FEM PurgeResults|Purge results]] |

|||

<!--T:16--> |

|||

You can also drag and drop a mesh to a Mechanical Analysis that does not have a mesh within the [[Tree_view|Tree view]]. |

|||

==== GMSH ==== <!--T:34--> |

|||

<!--T:45--> |

|||

# Select the model |

|||

# [[Image:FEM_MeshGmshFromShape.svg|24px]] [[FEM_MeshGmshFromShape|FEM mesh from shape by Gmsh]]: Generates a finite element mesh for a model using Gmsh. |

|||

# In the meshing dialog, click {{Button|Apply}} and {{Button|OK}}. |

|||

<!--T:18--> |

|||

We have now meshed our object and are ready to add constraints and forces. |

|||

=== Running the Solver === <!--T:37--> |

|||

==== Standard Procedure ==== <!--T:38--> |

|||

<!--T:22--> |

|||

# Select the solver object [[Image:FEM_SolverCalculixCxxtools.svg|24px]] contained in the '''Analysis''' container. |

|||

# Select [[Image:FEM_SolverControl.svg|24px]] [[FEM_SolverControl|Solver job control]] from the menu. |

|||

# Select '''Write .inp File'''. |

|||

# Select '''Run CalculiX'''. |

|||

# Click {{Button|OK}}. |

|||

==== Quick Procedure ==== <!--T:39--> |

|||

<!--T:25--> |

|||

# Select the solver object [[Image:FEM_SolverCalculixCxxtools.svg|24px]] contained in the '''Analysis''' container. |

|||

# Click on [[Image:FEM_SolverRun.svg|24px]] [[FEM_SolverRun|Run solver calculations]]. |

|||

=== Analyzing Results === <!--T:40--> |

|||

<!--T:23--> |

|||

# From the '''Object Tree''', select the '''CCX_Results''' object. |

|||

# Select [[Image:FEM_ResultShow.svg|24px|link=FEM_ResultShow]] [[FEM_ResultShow|Show result]]. |

|||

# Choose among the different Result types to view the results. |

|||

# The slider at the bottom can be used to alter the mesh visualization. This allows us to visualize the deformation experienced by the object, keep in mind that this is an approximation. |

|||

# To remove the results select [[Image:FEM_ResultsPurge.svg|24px|link=FEM_ResultsPurge]] [[FEM_ResultsPurge|Purge results]]. |

|||

<!--T:26--> |

|||

{{Note|Comparison to previous example file|If you select the '''Z displacement''' result type, you can see that the obtained value is almost identical to the test example provided by FreeCAD. Differences may occur due to the quality of the mesh and the number of nodes it possesses.}} |

|||

<!--T:7--> |

<!--T:7--> |

||

We are now finished with the basic workflow for the [[FEM |

We are now finished with the basic workflow for the [[FEM_Workbench|FEM Workbench]]. |

||

== Notes == <!--T:46--> |

|||

<!--T:47--> |

|||

* For a video tutorial based on this written tutorial watch: [https://www.youtube.com/watch?v=SZTIqhfCSVc FEM MaterialReinforced tutorial]. |

|||

<!--T:24--> |

|||

[[Category:User Documentation]] |

|||

[[Category:Tutorials]] |

|||

</translate> |

</translate> |

||

{{FEM Tools navi{{#translation:}}}} |

|||

{{clear}} |

|||

{{Userdocnavi{{#translation:}}}} |

|||

<languages/> |

|||

Latest revision as of 09:37, 27 March 2024

| Topic |

|---|

| Finite Element Analysis |

| Level |

| Beginner |

| Time to complete |

| 10 minutes + Solver time |

| Authors |

| Drei |

| FreeCAD version |

| 0.17 or above |

| Example files |

| None |

| See also |

| None |

Introduction

This tutorial is meant to introduce the reader to the basic workflow of the FEM Workbench, as well as most of the tools that are available to perform a static analysis.

Requirements

- FreeCAD version 0.17 or above.

- Netgen and/or GMSH is installed on the system (included in the FreeCAD installation).

- Calculix is installed on the system (included in the FreeCAD installation).

- The reader has the basic knowledge to use the Part and PartDesign Workbenches.

Procedure

Modeling

In this example a Cube is used as the study object, but any model created in the Part or PartDesign Workbenches can be used instead.

- Press the

Std New button to create a new document.

- Activate the

Part Workbench.

- Create a Cube.

- Change its Dimensions to the following:

- Length: 8.000 m.

- Width: 1.000 m.

- Height: 1.000 m.

Now we have a model to work with.

Creating the Analysis

- Activate the

FEM Workbench.

- Select the Model →

Analysis container option from the menu.

Constraints and Forces

- Hide the mesh from the Tree View.

- Show the original model.

- Select

Create FEM fixed constraint.

- Click Add, select the back face of the Cube object (face on the YZ axis) and click OK.

- Select

Create FEM force constraint.

- Click Add, select the front face of the Cube object (the face parallel to the back face) and set the Force [N] value to 9000000.

- Set the Direction to -Z by selecting one of the face edges parallel to that direction.

- Click OK.

We now have established the restrictions and forces for our static study.

Material

- Select

Material for solid and choose Calculix-Steel as the material.

- Click OK.

Meshing

It is recommended to make a mesh as the last step in the analysis preparations due to association to a geometry in FreeCAD. Depending on FreeCAD installation, there can be Netgen or GMSH meshers, you can use any of them.

Netgen

- Select the model.

FEM mesh from shape by Netgen: Generates a finite element mesh for a model using Netgen.

- In the meshing dialog, click Apply and OK.

You can also drag and drop a mesh to a Mechanical Analysis that does not have a mesh within the Tree view.

GMSH

- Select the model

FEM mesh from shape by Gmsh: Generates a finite element mesh for a model using Gmsh.

- In the meshing dialog, click Apply and OK.

We have now meshed our object and are ready to add constraints and forces.

Running the Solver

Standard Procedure

- Select the solver object

contained in the Analysis container.

- Select

Solver job control from the menu.

- Select Write .inp File.

- Select Run CalculiX.

- Click OK.

Quick Procedure

- Select the solver object

contained in the Analysis container.

- Click on

Run solver calculations.

Analyzing Results

- From the Object Tree, select the CCX_Results object.

- Select

Show result.

- Choose among the different Result types to view the results.

- The slider at the bottom can be used to alter the mesh visualization. This allows us to visualize the deformation experienced by the object, keep in mind that this is an approximation.

- To remove the results select

Purge results.

If you select the Z displacement result type, you can see that the obtained value is almost identical to the test example provided by FreeCAD. Differences may occur due to the quality of the mesh and the number of nodes it possesses.

We are now finished with the basic workflow for the FEM Workbench.

Notes

- For a video tutorial based on this written tutorial watch: FEM MaterialReinforced tutorial.

- Materials: Solid, Fluid, Nonlinear mechanical, Reinforced (concrete); Material editor

- Element geometry: Beam (1D), Beam rotation (1D), Shell (2D), Fluid flow (1D)

Constraints

- Electromagnetic: Electrostatic potential, Current density, Magnetization

- Geometrical: Plane rotation, Section print, Transform

- Mechanical: Fixed, Displacement, Contact, Tie, Spring, Force, Pressure, Centrif, Self weight

- Thermal: Initial temperature, Heat flux, Temperature, Body heat source

- Overwrite Constants: Constant vacuum permittivity

- Solve: CalculiX Standard, Elmer, Mystran, Z88; Equations: Deformation, Elasticity, Electrostatic, Electricforce, Magnetodynamic, Magnetodynamic 2D, Flow, Flux, Heat; Solver: Solver control, Solver run

- Results: Purge, Show; Postprocessing: Apply changes, Pipeline from result, Warp filter, Scalar clip filter, Function cut filter, Region clip filter, Contours filter, Line clip filter, Stress linearization plot, Data at point clip filter, Filter function plane, Filter function sphere, Filter function cylinder, Filter function box

- Additional: Preferences; FEM Install, FEM Mesh, FEM Solver, FEM CalculiX, FEM Concrete; FEM Element Types

- Getting started

- Installation: Download, Windows, Linux, Mac, Additional components, Docker, AppImage, Ubuntu Snap

- Basics: About FreeCAD, Interface, Mouse navigation, Selection methods, Object name, Preferences, Workbenches, Document structure, Properties, Help FreeCAD, Donate

- Help: Tutorials, Video tutorials

- Workbenches: Std Base, Arch, Assembly, CAM, Draft, FEM, Inspection, Mesh, OpenSCAD, Part, PartDesign, Points, Reverse Engineering, Robot, Sketcher, Spreadsheet, Surface, TechDraw, Test Framework

- Hubs: User hub, Power users hub, Developer hub