Path Workbench/de: Difference between revisions

| Line 69: | Line 69: | ||

* [[Image:Path-Engrave.png|32px]] [[Path_Engrave|Engrave]]: Erzeugt einen Pfad für Gravuren |

* [[Image:Path-Engrave.png|32px]] [[Path_Engrave|Engrave]]: Erzeugt einen Pfad für Gravuren |

||

* [[Image:Path-Face.png|32px]] [[Path_MillFace|Mill Face]]: |

* [[Image:Path-Face.png|32px]] [[Path_MillFace|Mill Face]]: Erzeugt einen Pfad zum Planen von Oberflächen |

||

* [[Image:Path-Helix.png|32px]] [[Path_Helix|Helix]]: Creates a helical path |

* [[Image:Path-Helix.png|32px]] [[Path_Helix|Helix]]: Creates a helical path |

||

Revision as of 21:09, 17 March 2018

Einleitung

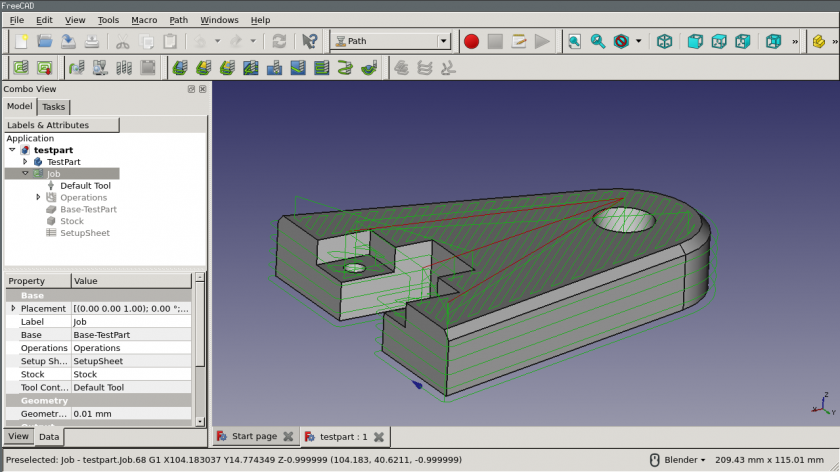

Im Path Arbeitsbereich können zum Betrieb von CNC Maschinen benötigte Befehlssätze erstellt werden. Unterstützt werden, Stand März 2018, Fräsen, Lasercutter, Graviermaschinen und ähnliche, 3 achsige CNC Maschinen deren Steuerung auf G-Code basiert. Die Path Postprozessoren erstellen G-Code in vielen verbreiteten Varianten, z.B. für Maschinencontroller von Centroid, Grbl, LinuCNC, Philips.

The FreeCAD Path Workbench workflow creates these machine instructions as follows:

- A 3D model is the base object, typically created using one or more of the Part Design, Part or Draft Workbenches.

- A Job is created in Path Workbench. This contains all the information required to generate the necessary G-Code to process the Job on a CNC mill: there is Stock material, the mill has a certain set of tools and it follows certain commands controlling speed and movements (usually G-Code).

- Tools are selected as required by the Job Operations.

- Milling paths are created using e.g. Contour and Pocket Operations. These Path objects use internal FreeCAD G-Code dialect, independent of the CNC machine.

Links für den schnellen Einstieg

- If you are a new new user trying to get familiar with Path, you might be interested in a fast walk-through tutorial.

- If you have a special machine which cannot use one of the available postprocessors you may want to learn about post-processor customization

- As an experienced user you may want to write a macro or automate a process might need to learn about scripting

- Power users who want to streamline their workflow can learn about customization.

- New developers who want to contribute to path might want to understand core concepts.

General concepts

The Path Workbench generates G-Code defining the paths required to mill the Project represented by the 3D model on the target mill—in [the Path Job Operations FreeCAD G-Code dialect ], which is later translated to the appropriate dialect for the target CNC controller by selecting the appropriate Postprocessor.

The G-Code is generated from directives and Operations contained in a Path Job. The Job Workflow lists these in the order they will be executed. The list is populated by adding Path Operations, Path Dressups, Path Partial Commands, and Path Modifications—from the Path Menu, or GUI buttons.

The Path Workbench provides a Tool Manager (Library, Tool-Table), and G-Code Inspection, and Simulation tools. It links the Postprocessor, and allows importing and exporting Job Templates.

The Path Workbench has external dependencies including:

- The FreeCAD 3D model units are defined in the Edit-> Preference...->General->Units tab's Units settings. The Postprocessor configuration defines the final G-Code units.

- The Macro file path, and Geometric tolerances, are defined in the Edit->Preferences...->Path->Job Preferences tab.

- Colors are defined in the Edit->Preferences...->Path->Path colors tab.

- Holding tag parameters are defined in the Edit->Preferences...->Path->Dressups tab.

- That the Base 3D model quality supports the Path WB requirements—passes Check Geometry.

FreeCAD Path Workbench internal G-Code dialect represents Feed rates in Units/Second—what the G-Code Inspection tool will show. The Postprocessor is configured to generate the appropriate Feed rates—either in Units/Second or Units/Minute for the target mill.

Path Kommandos

These commands are used for seting up a CNC project and manage your templates.

Job: Erstellt einen neuen CNC Job

Job: Erstellt einen neuen CNC Job

Post Process: Erstellt aus einem Job eine G-code Datei

Post Process: Erstellt aus einem Job eine G-code Datei

Export Template: Speichert den ausgewählten Job als Vorlage

Export Template: Speichert den ausgewählten Job als Vorlage

G-Code Inspector: Zeigt den G-code zur Überprüfung

G-Code Inspector: Zeigt den G-code zur Überprüfung

Simulator: Zeigt eine Simulation des Fräsvorgangs wie er auf der Maschine ausgeführt wird.

Simulator: Zeigt eine Simulation des Fräsvorgangs wie er auf der Maschine ausgeführt wird.

Tool Manager: Aufruf der Werkzeugtabelle

Tool Manager: Aufruf der Werkzeugtabelle

Complete Loop: Erstellt aus 2 ausgewählten Kanten einen geschlossenen Ring

Complete Loop: Erstellt aus 2 ausgewählten Kanten einen geschlossenen Ring

- File:Path Contour.png Contour: Erzeugt einen Fräspfad aus der Kontur des Basisobjekts

- File:Path-Profile-Face.png Profile from Face: Erzeugt einen Kontur- Fräspfad um eine ausgewälte Fläche

- File:Path-Profile-Edges.png Profile from Edges: Erzeugt einen Kontur- Fräspfad von ausgewählten Kanten

Pocket: Erzeugt einen Fräspfad für eine Tasche aus einer oder mehreren ausgewählten Taschen

Pocket: Erzeugt einen Fräspfad für eine Tasche aus einer oder mehreren ausgewählten Taschen

Drilling: Erzeugt den Pfad für eine oder mehrere Bohrungen

Drilling: Erzeugt den Pfad für eine oder mehrere Bohrungen

Engrave: Erzeugt einen Pfad für Gravuren

Engrave: Erzeugt einen Pfad für Gravuren

Mill Face: Erzeugt einen Pfad zum Planen von Oberflächen

Mill Face: Erzeugt einen Pfad zum Planen von Oberflächen

Helix: Creates a helical path

Helix: Creates a helical path

3D Pocket: Creates a path for a 3D pocket

3D Pocket: Creates a path for a 3D pocket

Path Dressup

Dogbone Dressup: Adds a dogbone dressup modification to a selected path

Dogbone Dressup: Adds a dogbone dressup modification to a selected path

Dragknife Dressup: Adds a dragknife dressup modification to a selected path

Dragknife Dressup: Adds a dragknife dressup modification to a selected path

Lead In Dressup: Adds a lead-in and/or lead-out point to a selected path

Lead In Dressup: Adds a lead-in and/or lead-out point to a selected path

Ramp Entry Dressup: Adds ramp entry dressup modification to a selected path

Ramp Entry Dressup: Adds ramp entry dressup modification to a selected path

Tag Dressup: Adds a holding tag dressup modification to a selected path

Tag Dressup: Adds a holding tag dressup modification to a selected path

Partial Commands

- File:Path SelectionPlane.png Plane: Changes the working plane of the machine

Fixture: Changes the fixture position

Fixture: Changes the fixture position

- File:Path ToolLenthOffset.png Tool Length Offset: Changes the offset of the current tool

Comment: Inserts a comment in the G-code of a path

Comment: Inserts a comment in the G-code of a path

Stop: Inserts a full stop of the machine

Stop: Inserts a full stop of the machine

Custom: Inserts custom G-code

Custom: Inserts custom G-code

Gcode From a Shape: Creates a path object from a selected Part object

Gcode From a Shape: Creates a path object from a selected Part object

Path Modification

Copy: Creates a parametric Copie of a selected path object

Copy: Creates a parametric Copie of a selected path object

Array: Creates an array by duplicating a selected path

Array: Creates an array by duplicating a selected path

Simple Copy: Creates a non-parametric copy of a selected path object

Simple Copy: Creates a non-parametric copy of a selected path object

Other

3D Surface: Creates a path for a 3D surface

3D Surface: Creates a path for a 3D surface

Feature area: Creates a feature area from selected objects

Feature area: Creates a feature area from selected objects

Feature area workplane: Creates a feature area workplane

Feature area workplane: Creates a feature area workplane

Path Errors: Checks the selected Job for missing values

Path Errors: Checks the selected Job for missing values

Scripting

The Path workbench offers a broad python scripting API. With it, you can create and modify paths from python scripts, or extend the available functionality of the workbench.

FAQ

The Path Workbench shares many concepts with other CAM software packages but has its own peculiarities. If something seems wrong, this might be a good place to start.