SheetMetal AddWall: Difference between revisions

(Create a template for SheetMetal) |

(V1.0 -> V0.21) Tag: Manual revert |

||

| (48 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

{{UnfinishedDocu{{#translation:}}}} |

|||

<languages/> |

<languages/> |

||

<translate> |

<translate> |

||

<!--T:1--> |

|||

{{Docnav |

{{Docnav |

||

|[[SheetMetal_AddBase|AddBase]] |

|||

| |

|||

|[[SheetMetal_Extrude|Extrude]] |

|||

| |

|||

|[[SheetMetal_Workbench|SheetMetal Workbench]] |

|[[SheetMetal_Workbench|SheetMetal Workbench]] |

||

|IconL= |

|IconL=SheetMetal_AddBase.svg |

||

|IconR=SheetMetal_Extrude.svg |

|||

|IconC=Sheetmetal_workbench_icon.svg |

|IconC=Sheetmetal_workbench_icon.svg |

||

|IconR= |

|||

}} |

}} |

||

<!--T:2--> |

|||

{{GuiCommand |

{{GuiCommand |

||

|Name=SheetMetal |

|Name=SheetMetal AddWall |

||

|MenuLocation=SheetMetal → |

|MenuLocation=SheetMetal → Make Wall |

||

|Workbenches=[[SheetMetal Workbench|SheetMetal]] |

|Workbenches=[[SheetMetal Workbench|SheetMetal]] |

||

|Shortcut= |

|Shortcut={{KEY|W}} |

||

|Version= |

|||

|SeeAlso= |

|||

}} |

}} |

||

==Description== |

==Description== <!--T:3--> |

||

<!--T:4--> |

|||

A description goes here |

|||

The [[Image:SheetMetal_AddWall.svg|24px]] '''SheetMetal AddWall''' command creates flanges on selected edges of a base plate. By changing the {{PropertyData|angle}} property a flange it can be turned into a hem. |

|||

<!--T:36--> |

|||

:[[Image:Involute-Gear example.png]] |

|||

A '''flange''' consists of a 90° cylindrical bend and a planar strip (wall). |

|||

:{{Caption|From left to right: caption in here |

|||

}} |

|||

</translate> |

|||

==Usage== |

|||

[[Image:SheetMetal_AddWall-12.png|200px]] [[Image:Button_right.svg|16px|link=]] |

|||

[[Image:SheetMetal_AddWall-13.png|200px]] |

|||

<translate> |

|||

<!--T:37--> |

|||

{{Caption|Two selected edges → two flanges}} |

|||

<!--T:38--> |

|||

# Switch to the [[Image:FCGear_workbench_icon.svg|22px]] [[FCGear Workbench]]. |

|||

Resetting the {{PropertyData|angle}} property to about 180° in a second step will create a '''hem''' instead. |

|||

# Invoke the command several way: |

|||

#* Press the [[File:FCGear_InvoluteGear.svg|22px|link=FCGear InvoluteGear]] [[FCGear_InvoluteGear|Create an Involute gear]] button in the tool bar. |

|||

#* Using the {{MenuCommand|Gear Menu → Involute gear}}. |

|||

# Change the gear parameter to the required conditions (see {{Emphasis|Properties → Data}} below). |

|||

</translate> |

|||

==Properties== |

|||

[[Image:SheetMetal_AddWall-14.png|200px]] [[Image:Button_right.svg|16px|link=]] |

|||

[[Image:SheetMetal_AddWall-15.png|200px]] |

|||

<translate> |

|||

<!--T:39--> |

|||

{{Caption|Two selected edges → two hems}} |

|||

== |

==Usage== <!--T:5--> |

||

<!--T:6--> |

|||

{{Properties_Title|Base}} |

|||

# Select one or more edge(s) of a base plate. |

|||

# Activate the [[Image:SheetMetal_AddWall.svg|16px]] '''SheetMetal AddWall''' command using one of the following: |

|||

#* The {{Button|[[Image:SheetMetal_AddWall.svg|16px]] [[SheetMetal_AddWall|Make Wall]]}} button. |

|||

#* The {{MenuCommand|SheetMetal → [[Image:SheetMetal_AddWall.svg|16px]] Make Wall}} menu option. |

|||

#* The keyboard shortcut: {{KEY|W}}. |

|||

==Notes== <!--T:40--> |

|||

* {{PropertyData|Placement}}: [[Placement|Placement]] is the location and orientation of an object in space. |

|||

* {{PropertyData|Label}}: User name of the object in the [[Tree_view|Tree view]]. |

|||

<!--T:7--> |

|||

{{Properties_Title|computed}} |

|||

To create a base plate use a closed 2D outline - preferably a [[File:Sketcher_NewSketch.svg|16px]] [[Sketcher NewSketch|Sketch]] - with the [[Image:SheetMetal_AddBase.svg|16px]] [[SheetMetal_AddBase|Make Base Wall]] command. |

|||

<!--T:41--> |

|||

* {{PropertyData|dw}}: Pitch diameter (not changeable, is calculated automatically). |

|||

Alternatively a base plate (blank) can be created with commands from the [[Image:Workbench_Part.svg|16px]] [[Part_Workbench|Part Workbench]] or [[Image:Workbench_PartDesign.svg|16px]] [[PartDesign_Workbench|PartDesign Workbench]]. |

|||

<!--T:42--> |

|||

{{Properties_Title|gear_parameter}} |

|||

To create a blank with the [[Part_Workbench|Part Workbench]]: |

|||

# Create a solid using either: |

|||

#* [[File:Part_Box.svg|16px]] [[Part_Box|Part Box]]. |

|||

#* [[File:Part_Extrude.svg|16px]] [[Part_Extrude|Part Extrude]] from: |

|||

#** A [[File:Draft_Rectangle.svg|16px]] [[Draft_Rectangle|Draft Rectangle]]. |

|||

#** A [[File:Draft_Wire.svg|16px]] [[Draft_Wire|Draft Wire]]. |

|||

#** A [[File:Sketcher_NewSketch.svg|16px]] [[Sketcher_NewSketch|Sketch]]. |

|||

# Make sure one the dimensions of the Box or the extrusion distance equals the sheet metal thickness. |

|||

<!--T:43--> |

|||

* {{PropertyData|beta}}: With the helix angle β a helical gear is created (positive value → rotation direction right, negative value → rotation direction left). |

|||

To create a blank with the [[PartDesign_Workbench|PartDesign Workbench]]: |

|||

* {{PropertyData|clearance}}: Default is 0,25 (see also the information in {{Emphasis|Notes}}). |

|||

# Create a solid using either: |

|||

* {{PropertyData|double_gear}}: {{Emphasis|True}} creates a double helix gear (see also the information in {{Emphasis|Notes}}) |

|||

#* [[File:PartDesign_AdditiveBox.svg|16px]] [[PartDesign_AdditiveBox|Additive Box]]. |

|||

* {{PropertyData|head}}: Default is 0,00. This value is used to change the tooth height. |

|||

#* [[File:PartDesign_Pad.svg|16px]] [[PartDesign Pad]] from a [[File:Sketcher_NewSketch.svg|16px]] [[Sketcher NewSketch|Sketch]]. |

|||

* {{PropertyData|height}}: Value of the gear width. |

|||

# Make sure one the dimensions of the Box or the {{PropertyData|Length}} property of the Pad equals the sheet metal thickness. |

|||

* {{PropertyData|module}}: Module is the ratio of the reference diameter of the gear divided by the number of teeth (see also the information in {{Emphasis|Notes}}). |

|||

* {{PropertyData|numpoints}}: Default is 6, change of the involute profile. Changing the value can lead to unexpected results. |

|||

* {{PropertyData|properties_from_tool}}: If helix angle β is given and {{Emphasis|properties_from-tool}} is enabled, gear parameters are internally recomputed for the rotated gear. |

|||

* {{PropertyData|shift}}: Default is 0,00, generates a positive and negative profile shift (see also the information in {{Emphasis|Notes}}). |

|||

* {{PropertyData|simple}}: {{Emphasis|True}} generates a simplified display (without teeth and only a cylinder in pitch diameter). |

|||

* {{PropertyData|teeth}}: Number of teeth (see also the information in {{Emphasis|Notes}}) |

|||

* {{PropertyData|undercut}}: {{Emphasis|True}} changes the profil of the tooth root (see also the information in {{Emphasis|Notes}}). |

|||

<!--T:8--> |

|||

{{Properties_Title|involute_parameter}} |

|||

If you start with a [[File:PartDesign_Body.svg|16px]] [[PartDesign_Body|PartDesign Body]], you can mix SheetMetal features with PartDesign features such as [[File:PartDesign_Pocket.svg|16px]] [[PartDesign_Pocket|PartDesign Pocket]] or [[File:PartDesign_Hole.svg|16px]] [[PartDesign_Hole|PartDesign Hole]]. |

|||

==Properties== <!--T:9--> |

|||

* {{PropertyData|pressure_parameter}}: Default is 20 (see also the information in {{Emphasis|Notes}}). |

|||

<!--T:26--> |

|||

{{Properties_Title|tolerance}} |

|||

See also: [[Property_editor|Property editor]]. |

|||

<!--T:27--> |

|||

* {{PropertyData|backslash}}: Default is 0,00. Backlash, also called lash or play, is the distance between the teeths at a gear pair. |

|||

A SheetMetal Bend object is derived from a [[Part_Feature|Part Feature]] object and inherits all its properties. It also has the following additional properties and its label has a default value: |

|||

* {{PropertyData|reversed_backslash}}: {{Emphasis|True}} backlash decrease or {{Emphasis|False}} backlash increase (see also the information in {{Emphasis|Notes}}). |

|||

=== |

===Data=== <!--T:10--> |

||

<!--T:11--> |

|||

The parameter descriptions of the {{Emphasis|View}} tab will be found in [[Property_editor|Property editor]], further below at {{Emphasis|Example of the properties of a PartDesign object}}. |

|||

{{Properties_Title|Base}} |

|||

<!--T:12--> |

|||

==Notes== |

|||

* {{PropertyData|Label|String}}: Default value: {{value|Bend}} (+ a sequential number for second and following items). </br>The user editable name of this object, it may be any arbitrary UTF8 string. |

|||

* {{PropertyData|Base Feature|Link|hidden}}: Base Feature. Link to the parent feature. |

|||

* {{PropertyData|_Body|LinkHidden|hidden}}: Hidden link to the parent body. |

|||

<!--T:13--> |

|||

* {{Emphasis|clearance}}: At a gear pair, clearance is the distance between the tooth tip of the first gear and the tooth root of the second gear. |

|||

{{Properties_Title|Parameters}} |

|||

* {{Emphasis|double_gear}}: To use the double helical gearing the helix angle β ({{Emphasis|beta}}) for the helical gearing must first be entered. |

|||

* {{Emphasis|module}}: Using ISO (International Organization for Standardization) guidelines, Module size is designated as the unit representing gear tooth-sizes. Module (m): m = 1 (p = 3.1416), m = 2 (p = 6.2832), m = 4 (p = 12.566). If you multiply Module by Pi, you can obtain Pitch (p). Pitch is the distance between corresponding points on adjacent teeth. |

|||

* {{Emphasis|shift}}: Profile shift is not merely used to prevent undercut. It can be used to adjust center distance between two gears. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. |

|||

* {{Emphasis|teeth}}: If the number of teeth is changed, the pitch diameter also changes ({{Emphasis|dw}}). |

|||

* {{Emphasis|undercut}}: Undercut is used when the number of teeth of a gear is too small. Otherwise the mating gear will cut into the tooth root. The undercut not only weakens the tooth with a wasp-like waist, but also removes some of the useful involute adjacent to the base circle. |

|||

* {{Emphasis|pressure_parameter}}: 20° is a standard value here. The pressure angle is defined as the angle between the line-of-action (common tangent to the base circles) and a perpendicular to the line-of-centers. Thus, for standard gears, 14.5° pressure angle gears have base circles much nearer to the roots of teeth than 20° gears. It is for this reason that 14.5° gears encounter greater undercutting problems than 20° gears. Important. the pressure angle changes with a profile shift. Only change the parameter, if sufficient knowledge of the gear geometry is available. |

|||

* {{Emphasis|reversed_backslash}}: If there are several gears, pay attention to which gear the parameter is set for. |

|||

<!--T:14--> |

|||

==Limitations== |

|||

* {{PropertyData|Bend Type|Enumeration}}: "Bend Type". {{value|Material Outside}} (default), {{value|Material Inside}}, {{value|Thickness Outside}}, {{value|Offset}}. |

|||

* {{PropertyData|Length Spec|Enumeration}}: "Type of Length Specification". {{value|Leg}} (default), {{value|Outer Sharp}}, {{value|Inner Sharp}}, {{value|Tangential}}. {{Version|0.21}} |

|||

* {{PropertyData|angle|Angle}}: "Bend Angle". Default angle: {{value|90,00°}}. |

|||

* {{PropertyData|base Object|LinkSub}}: "Base Object". Link to the planar face to receive a bend. |

|||

* {{PropertyData|gap1|Distance}}: "Gap from Left side". Default: {{value|0,00 mm}}. |

|||

* {{PropertyData|gap2|Distance}}: "Gap from Right side". Default: {{value|0,00 mm}}. |

|||

* {{PropertyData|invert|Bool}}: "Invert Bend Direction". Default: {{FALSE}}. |

|||

* {{PropertyData|length|Length}}: "Length of Wall". Default: {{value|10,00 mm}}. |

|||

* {{PropertyData|radius|Length}}: "Bend Radius". Default: {{value|1,00 mm}}. |

|||

<!--T:28--> |

|||

Limitation are not known yet. |

|||

{{Properties_Title|Parameters Ex}} |

|||

<!--T:29--> |

|||

==Scripting== |

|||

* {{PropertyData|Auto Miter|Bool}}: "Enable Auto Miter". Default: {{TRUE}}. |

|||

* {{PropertyData|extend1|Distance}}: "Extend from Left Side". Default: {{value|0,00 mm}}. |

|||

* {{PropertyData|extend2|Distance}}: "Extend from Right Side". Default: {{value|0,00 mm}}. |

|||

* {{PropertyData|kfactor|FloatConstraint}}: "Location of Neutral Line. Caution: Using ANSI standards, not DIN.". </br> Default: {{value|0,50}}. K factor (also known as neutral factor) for the bend. Used to calculate bend allowance when unfolding. |

|||

* {{PropertyData|max Extend Dist|Length}}: "Auto Miter maximum Extend Distance". Default: {{value|5,00 mm}}. |

|||

* {{PropertyData|min Gap|Length}}: "Auto Miter Minimum Gap". Default: {{value|5,00 mm}}. |

|||

* {{PropertyData|miterangle1|Angle}}: "Bend Miter Angle from Left Side". Default angle: {{value|0,00°}}. |

|||

* {{PropertyData|miterangle2|Angle}}: "Bend Miter Angle from Right Side". Default angle: {{value|0,00°}}. |

|||

* {{PropertyData|offset|Distance}}: "Offset Bend". Default: {{value|0,00 mm}}. |

|||

* {{PropertyData|unfold|Bool}}: "Shows Unfold View of Current Bend". Default: {{FALSE}} </br> {{TRUE}} unfolds the bend. |

|||

<!--T:30--> |

|||

{{Properties_Title|Parameters Ex2}} |

|||

<!--T:31--> |

|||

* {{PropertyData|Sketch|Link}}: "Sketch Object". |

|||

* {{PropertyData|sketchflip|Bool}}: "Flip Sketch Direction". Default: {{FALSE}}. |

|||

* {{PropertyData|sketchinvert|Bool}}: "Invert Sketch Start". Default: {{FALSE}}. |

|||

<!--T:32--> |

|||

{{Properties_Title|Parameters Ex3}} |

|||

<!--T:33--> |

|||

* {{PropertyData|Length List|FloatList}}: "Length of Wall List". Default: {{value|[10,00]}}. |

|||

* {{PropertyData|bend AList|FloatList}}: "Bend Angle List". Default: {{value|[90,00]}}. |

|||

<!--T:34--> |

|||

{{Properties_Title|Parameters Relief}} |

|||

<!--T:35--> |

|||

* {{PropertyData|Relief Factor|Float}}: "Relief Factor". Default: {{value|0,70}}. |

|||

* {{PropertyData|Use Relief Factor|Bool}}: "Use Relief Factor". Default: {{FALSE}}. |

|||

* {{PropertyData|min Relief Gap|Length}}: "Minimum Gap to Relief Cut". Default: {{value|1,00 mm}}. |

|||

* {{PropertyData|relief Type|Enumeration}}: "Relief Type". {{value|Rectangle}} (default), {{value|Round}}. Enabled only when a gap value is set. |

|||

* {{PropertyData|reliefd|Length}}: "Relief Depth". Default: {{value|1,00 mm}}. Enabled only when a gap value is set. |

|||

* {{PropertyData|reliefw|Length}}: "Relief Width". Default: {{value|0,80 mm}}. Enabled only when a gap value is set. |

|||

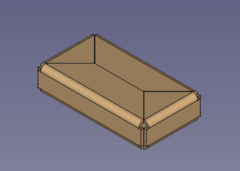

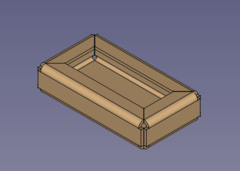

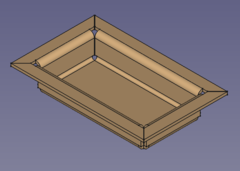

== Example == <!--T:18--> |

|||

Use the power of python to automate your gear modeling: |

|||

</translate> |

</translate> |

||

[[Image:SheetMetal_AddWall-01.png|300px]] |

|||

{{Code|code= |

|||

import FreeCAD as App |

|||

import freecad.gears.commands |

|||

gear = freecad.gears.commands.CreateInvoluteGear.create() |

|||

gear.teeth = 20 |

|||

gear.beta = 20 |

|||

gear.height = 10 |

|||

gear.double_helix = True |

|||

App.ActiveDocument.recompute() |

|||

Gui.SendMsgToActiveView("ViewFit") |

|||

}} |

|||

<translate> |

<translate> |

||

<!--T:19--> |

|||

{{Caption|A simple tray}} |

|||

<div class="mw-collapsible mw-collapsed"> |

|||

<div class="mw-collapsible-content"> |

|||

=== Preparation === <!--T:20--> |

|||

<!--T:21--> |

|||

This tray is made of a rectangular blank with walls added to its outline edges. |

|||

And so one outline sketch for the blank has to be prepared in advance. |

|||

</translate> |

|||

[[Image:SheetMetal_AddWall-02.png|200px]] |

|||

<translate> |

|||

<!--T:22--> |

|||

{{Caption|Just a rectangular outline}} |

|||

=== Workflow === <!--T:23--> |

|||

<!--T:24--> |

|||

# Create a blank |

|||

## Select the outline sketch </br> [[Image:SheetMetal_AddWall-03.png|240px]] |

|||

## Press the {{Button|[[Image:SheetMetal_AddBase.svg|16px]] [[SheetMetal_AddBase|Make Base Wall]]}} button </br> or use the keyboard shortcut: {{KEY|C}} then {{KEY|F}} </br> [[Image:SheetMetal_AddWall-04.png|240px]] </br> (The blank is padded in z direction </br> </br> |

|||

# Add walls to the outline edges |

|||

## Select the blank's '''outline edges''' </br> [[Image:SheetMetal_AddWall-05.png|240px]] |

|||

## Press the {{Button|[[Image:SheetMetal_AddWall.svg|16px]] [[SheetMetal_AddWall|Make Wall]]}} button </br> or use the keyboard shortcut: {{KEY|W}} </br> [[Image:SheetMetal_AddWall-06.png|240px]] |

|||

## If the fold is 90° down set the value of '''invert''' property to true to reverse the direction (and '''length''' to a lower value for smaller walls) </br> [[Image:SheetMetal_AddWall-01.png|240px]] </br> </br> |

|||

# Add some more walls |

|||

## Select the tray's '''upper outside edges''' </br> [[Image:SheetMetal_AddWall-08.png|240px]] |

|||

## Press the {{Button|[[Image:SheetMetal_AddWall.svg|16px]] [[SheetMetal_AddWall|Make Wall]]}} button </br> or use the keyboard shortcut: {{KEY|W}} </br> [[Image:SheetMetal_AddWall-09.png|240px]] </br> |

|||

## The walls are a bit too long (but nicely trimmed) and so the '''length''' property has to be set to a lower value </br> [[Image:SheetMetal_AddWall-10.png|240px]] |

|||

## If you like the folds swing outward set the '''invert''' value to true </br> [[Image:SheetMetal_AddWall-11.png|240px]] |

|||

<!--T:25--> |

|||

Done! |

|||

</div> <!-- End of collapsible element for content section. Do not remove! --> |

|||

</div> <!-- End of collapsible element for ... section. Do not remove! --> |

|||

<!--T:17--> |

|||

{{Docnav |

{{Docnav |

||

|[[SheetMetal_AddBase|AddBase]] |

|||

| |

|||

|[[SheetMetal_Extrude|Extrude]] |

|||

| |

|||

|[[SheetMetal_Workbench|SheetMetal Workbench]] |

|[[SheetMetal_Workbench|SheetMetal Workbench]] |

||

|IconL= |

|IconL=SheetMetal_AddBase.svg |

||

|IconR=SheetMetal_Extrude.svg |

|||

|IconC=Sheetmetal_workbench_icon.svg |

|IconC=Sheetmetal_workbench_icon.svg |

||

|IconR= |

|||

}} |

}} |

||

</translate> |

</translate> |

||

[[Category:Addons{{#translation:}}]] |

|||

[[Category:SheetMetal{{#translation:}}]] |

[[Category:SheetMetal{{#translation:}}]] |

||

[[Category:Addons{{#translation:}}]] |

|||

[[Category:External Command Reference{{#translation:}}]] |

[[Category:External Command Reference{{#translation:}}]] |

||

Latest revision as of 20:29, 29 April 2023

This documentation is not finished. Please help and contribute documentation.

GuiCommand model explains how commands should be documented. Browse Category:UnfinishedDocu to see more incomplete pages like this one. See Category:Command Reference for all commands.

See WikiPages to learn about editing the wiki pages, and go to Help FreeCAD to learn about other ways in which you can contribute.

|

|

| Menu location |

|---|

| SheetMetal → Make Wall |

| Workbenches |

| SheetMetal |

| Default shortcut |

| W |

| Introduced in version |

| - |

| See also |

| None |

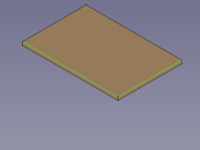

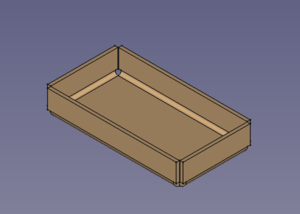

Description

The SheetMetal AddWall command creates flanges on selected edges of a base plate. By changing the Dataangle property a flange it can be turned into a hem.

A flange consists of a 90° cylindrical bend and a planar strip (wall).

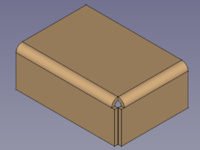

Two selected edges → two flanges

Resetting the Dataangle property to about 180° in a second step will create a hem instead.

Two selected edges → two hems

Usage

- Select one or more edge(s) of a base plate.

- Activate the

SheetMetal AddWall command using one of the following:

- The

Make Wall button.

- The SheetMetal →

Make Wall menu option.

- The keyboard shortcut: W.

- The

Notes

To create a base plate use a closed 2D outline - preferably a Sketch - with the

Make Base Wall command.

Alternatively a base plate (blank) can be created with commands from the Part Workbench or

PartDesign Workbench.

To create a blank with the Part Workbench:

- Create a solid using either:

Part Box.

Part Extrude from:

- A

Draft Rectangle.

- A

Draft Wire.

- A

Sketch.

- A

- Make sure one the dimensions of the Box or the extrusion distance equals the sheet metal thickness.

To create a blank with the PartDesign Workbench:

- Create a solid using either:

Additive Box.

PartDesign Pad from a

Sketch.

- Make sure one the dimensions of the Box or the DataLength property of the Pad equals the sheet metal thickness.

If you start with a PartDesign Body, you can mix SheetMetal features with PartDesign features such as

PartDesign Pocket or

PartDesign Hole.

Properties

See also: Property editor.

A SheetMetal Bend object is derived from a Part Feature object and inherits all its properties. It also has the following additional properties and its label has a default value:

Data

Base

- DataLabel (

String): Default value:Bend(+ a sequential number for second and following items).

The user editable name of this object, it may be any arbitrary UTF8 string. - Data (hidden)Base Feature (

Link): Base Feature. Link to the parent feature. - Data (hidden)_Body (

LinkHidden): Hidden link to the parent body.

Parameters

- DataBend Type (

Enumeration): "Bend Type".Material Outside(default),Material Inside,Thickness Outside,Offset. - DataLength Spec (

Enumeration): "Type of Length Specification".Leg(default),Outer Sharp,Inner Sharp,Tangential. introduced in version 0.21 - Dataangle (

Angle): "Bend Angle". Default angle:90,00°. - Database Object (

LinkSub): "Base Object". Link to the planar face to receive a bend. - Datagap1 (

Distance): "Gap from Left side". Default:0,00 mm. - Datagap2 (

Distance): "Gap from Right side". Default:0,00 mm. - Datainvert (

Bool): "Invert Bend Direction". Default:false. - Datalength (

Length): "Length of Wall". Default:10,00 mm. - Dataradius (

Length): "Bend Radius". Default:1,00 mm.

Parameters Ex

- DataAuto Miter (

Bool): "Enable Auto Miter". Default:true. - Dataextend1 (

Distance): "Extend from Left Side". Default:0,00 mm. - Dataextend2 (

Distance): "Extend from Right Side". Default:0,00 mm. - Datakfactor (

FloatConstraint): "Location of Neutral Line. Caution: Using ANSI standards, not DIN.".

Default:0,50. K factor (also known as neutral factor) for the bend. Used to calculate bend allowance when unfolding. - Datamax Extend Dist (

Length): "Auto Miter maximum Extend Distance". Default:5,00 mm. - Datamin Gap (

Length): "Auto Miter Minimum Gap". Default:5,00 mm. - Datamiterangle1 (

Angle): "Bend Miter Angle from Left Side". Default angle:0,00°. - Datamiterangle2 (

Angle): "Bend Miter Angle from Right Side". Default angle:0,00°. - Dataoffset (

Distance): "Offset Bend". Default:0,00 mm. - Dataunfold (

Bool): "Shows Unfold View of Current Bend". Default:false

trueunfolds the bend.

Parameters Ex2

- DataSketch (

Link): "Sketch Object". - Datasketchflip (

Bool): "Flip Sketch Direction". Default:false. - Datasketchinvert (

Bool): "Invert Sketch Start". Default:false.

Parameters Ex3

- DataLength List (

FloatList): "Length of Wall List". Default:[10,00]. - Databend AList (

FloatList): "Bend Angle List". Default:[90,00].

Parameters Relief

- DataRelief Factor (

Float): "Relief Factor". Default:0,70. - DataUse Relief Factor (

Bool): "Use Relief Factor". Default:false. - Datamin Relief Gap (

Length): "Minimum Gap to Relief Cut". Default:1,00 mm. - Datarelief Type (

Enumeration): "Relief Type".Rectangle(default),Round. Enabled only when a gap value is set. - Datareliefd (

Length): "Relief Depth". Default:1,00 mm. Enabled only when a gap value is set. - Datareliefw (

Length): "Relief Width". Default:0,80 mm. Enabled only when a gap value is set.

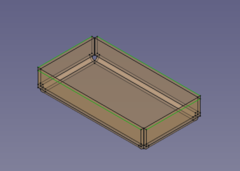

Example

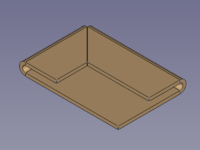

A simple tray

Preparation

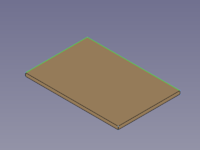

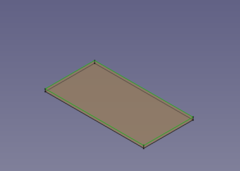

This tray is made of a rectangular blank with walls added to its outline edges. And so one outline sketch for the blank has to be prepared in advance.

Just a rectangular outline

Workflow

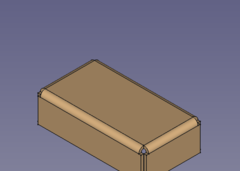

- Create a blank

- Select the outline sketch

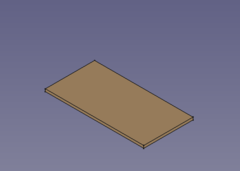

- Press the

Make Base Wall button

or use the keyboard shortcut: C then F

(The blank is padded in z direction

- Select the outline sketch

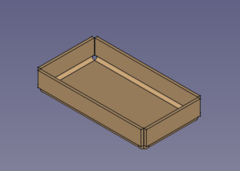

- Add walls to the outline edges

- Select the blank's outline edges

- Press the

Make Wall button

or use the keyboard shortcut: W

- If the fold is 90° down set the value of invert property to true to reverse the direction (and length to a lower value for smaller walls)

- Select the blank's outline edges

- Add some more walls

- Select the tray's upper outside edges

- Press the

Make Wall button

or use the keyboard shortcut: W

- The walls are a bit too long (but nicely trimmed) and so the length property has to be set to a lower value

- If you like the folds swing outward set the invert value to true

- Select the tray's upper outside edges

Done!