SheetMetal Forming: Difference between revisions

(Removed the inherited properties - thanks for the hint.) |

No edit summary |

||

| Line 40: | Line 40: | ||

== Properties == <!--T:6--> |

== Properties == <!--T:6--> |

||

See also: [[ |

See also: [[Property_editor|Property editor]]. |

||

A SheetMetal WallForming object is derived from a [[Part_Feature|Part Feature]] object and inherits all its properties. It also has the following additional properties: |

A SheetMetal WallForming object is derived from a [[Part_Feature|Part Feature]] object and inherits all its properties. It also has the following additional properties: |

||

Revision as of 20:24, 23 August 2021

This documentation is not finished. Please help and contribute documentation.

GuiCommand model explains how commands should be documented. Browse Category:UnfinishedDocu to see more incomplete pages like this one. See Category:Command Reference for all commands.

See WikiPages to learn about editing the wiki pages, and go to Help FreeCAD to learn about other ways in which you can contribute.

|

|

| Menu location |

|---|

| SheetMetal → Make Forming in Wall |

| Workbenches |

| SheetMetal |

| Default shortcut |

| M F |

| Introduced in version |

| - |

| See also |

| None |

Description

The SheetMetal Forming command creates an embossed shape in a SheetMetal wall using a separate solid object.

The back side plane of the shapedefining solid is used to position and orient the embossed shape, i.e. their local coordinate systems will have the same origin and the same orientation by default.

The angle around the z-axis and offsets in x, y, and z direction may be altered by changing the parameter values in the properties window.

Usage

- Select the wall of the SheetMetal object to be embossed

- Select the back side of the shape defining solid

- Note: Don't forget the Control/Command key!

- Activate the

Make Forming in Wall command using:

Make Forming in Wall button

- SheetMetal →

Make Forming in Wall drop down menu

- keyboard shortcut: M then F

Properties

See also: Property editor.

A SheetMetal WallForming object is derived from a Part Feature object and inherits all its properties. It also has the following additional properties:

Data

Base

- DataLabel (

String): Default value:WallForming(+ a sequential number for second and following items).

The user editable name of this object, it may be any arbitrary UTF8 string. - Data (hidden)Base Feature (

Link): Base Feature. Link to the parent feature. - Data (hidden)_Body (

LinkHidden):

Parameters

- DataSuppress Feature (

Bool): "Suppress Forming Feature". Default value isfalse. - Dataangle (

Angle): "Tool Position Angle". Default angle:0,00°. - Database Object (

LinkSub): "Base Object". Link to the planar face to be embossed. - Dataoffset (

VectorDistance): "Offset from Center of Face". Default:[0,00 mm, 0,00 mm, 0,00 mm]. - Datathickness (

Distance): "Thickness of Sheetmetal". Thickness of the Data (hidden)Base Feature:. - Datatool Object (

LinkSub): "Forming Tool Object". Link to the planar face used to position the Forming Tool

Parameters1

- DataSketch (

Link): "Point Sketch on Sheetmetal".

Example

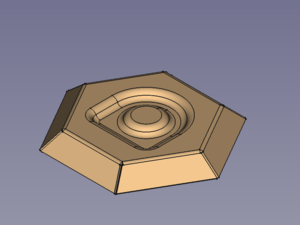

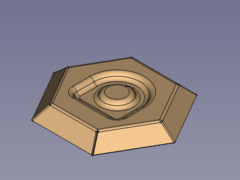

A hexagon bowl with embossed centre

Preparation

This bowl is made of a folded sheet metal object with a shape embossed, both have to be prepared in advance.

No need to work with coplanar sketches here.

SheetMetal bowl and embossing object

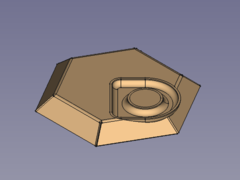

Workflow

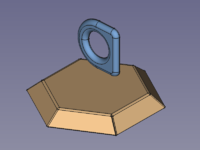

- Select the wall of the SheetMetal object to be embossed

- Select the back side of the shape defining solid

- Press the

Make Forming in Wall button

or use the keyboard shortcut: M then F

Done!

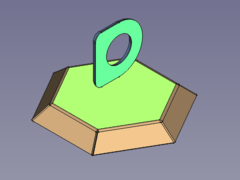

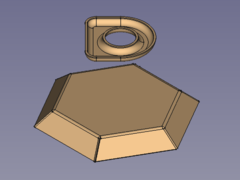

- Alter orientation and position

- Activate the

WallForming object in the Tree view

- Set the value of the parameter angle to e.g. 45°

- Set the value of the parameter offset, x to e.g. greater than 0

Here it is plain to see that it doesn't make sense to move the embossed geometry outside the selected wall.

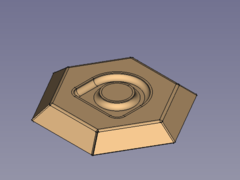

- Setting the value of the parameter offset, z to e.g. greater than 0 isn't any better:

At least the FreeCAD doesn't crash when a part has two bodies...

- Activate the

- Some hints

- The height of the defining solid determines the depth of the embossed shape.

That means changing the parameter offset, z to alter the depth won't deliver expected results. - The embossed geometry is made of a shell object i.e. it has a constant thickness.

And so the defining solid has to be offsetable, otherwise the tool will fail to create the emboss.

- The height of the defining solid determines the depth of the embossed shape.