FCGear CrownGear: Difference between revisions

m (Added pagination) |

BavariaSHAPE (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

{{Page in progress}} |

|||

<languages/> |

<languages/> |

||

<translate> |

<translate> |

||

| Line 19: | Line 17: | ||

|Shortcut=None |

|Shortcut=None |

||

|Version=v0.16 |

|Version=v0.16 |

||

|SeeAlso=[[FCGear |

|SeeAlso=[[FCGear InvoluteGear]] |

||

}} |

}} |

||

==Description== |

==Description== |

||

The crown wheel resembles a ring-shaped curved rack. The pressure angle decreases continuously from the outer to the inner diameter. Thus, the variable peripheral speed at the crown wheel is compensated against the constant peripheral speed of the pinion. The pointed outer teeth and the steep tooth flanks on the inner diameter limit the usable tooth width. Crown gears achieve similar efficiencies as spur gears. One crown gear can drive several pinions. |

|||

<span style="color:#FF0000">'''''This and the linked website(s) are under construction since 8.3.2020. I try to fill the content quickly in addition to my job. Therefore please have a little patience. @bavariaSHAPE'''''</span> |

|||

Known field of application of crown gears: |

|||

* Rear axle drives for cars and motorcycles |

|||

Crown wheels come from antiquity and the Middle Ages. They were replaced by bevel gears over the years, as they were easier to calculate and manufacture. Crown wheels were used in grain and oil mills. They became famous in historic motorcycles as the so-called royal wave. |

|||

* Swivel mechanism for operating tables |

|||

* Angular milling heads |

|||

* Powered tool systems with multiple pinions and a crown gear |

|||

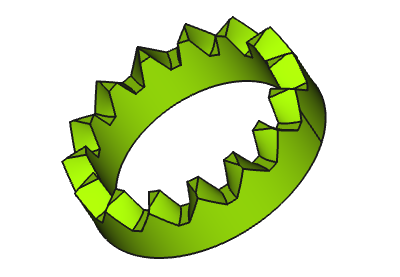

:[[File:Crown-Gear example.png]] |

:[[File:Crown-Gear example.png]] |

||

:{{Caption|Above: Crown gear}} |

:{{Caption|Above: Crown gear}} |

||

==Usage== |

|||

# Switch to the [[Image:FCGear_workbench_icon.svg|22px]] [[FCGear Workbench]]. |

|||

# Invoke the command several way: |

|||

#* Press the [[File:FCGear_CrownGear.svg|22px|link=FCGear CrownGear]] [[FCGear_CrownGear|Create a Crown gear]] button in the tool bar. |

|||

#* Using the {{MenuCommand|Menu → Crown gear}}. |

|||

# Change the gear parameter to the required conditions (see {{Emphasis|Properties → Data}} below). |

|||

==Properties== |

|||

===Data=== |

|||

{{Properties_Title|Base}} |

|||

* {{PropertyData|Placement}}: [[Placement|Placement]] is the location and orientation of an object in space. |

|||

* {{PropertyData|Label}}: User name of the object in the [[Tree_view|Tree view]]. |

|||

{{Properties_Title|accuracy}} |

|||

* {{PropertyData|construct}}: Default is {{Emphasis|True}}. Change to {{Emphasis|False}} and the construction component disappears. |

|||

* {{PropertyData|num_profiles}}: Number of profiles used for loft. |

|||

{{Properties_Title|gear_parameter}} |

|||

* {{PropertyData|height}}: Value for the gear width. |

|||

* {{PropertyData|module}}: Module is the ratio of the reference diameter of the gear divided by the number of teeth (see also the information in {{Emphasis|Note}}). |

|||

* {{PropertyData|other_teeth}}: Number of teeth of the other gear (pinion). See also the information in {{Emphasis|Note}}. |

|||

* {{PropertyData|teeth}}: Number of teeth |

|||

* {{PropertyData|thickness}}: Height from the tip of tooth to the lower side of the gear ring. |

|||

{{Properties_Title|involute_parameter}} |

|||

* {{PropertyData|pressure_parameter}}: Default is 20 (see also the information in {{Emphasis|Note}}). |

|||

=== View === |

|||

The parameter descriptions of the {{Emphasis|View}} tab will be found in [[Property_editor|Property editor]], further below at {{Emphasis|Example of the properties of a PartDesign object}}. |

|||

==Notes== |

|||

* {{Emphasis|module}}: Using ISO (International Organization for Standardization) guidelines, Module size is designated as the unit representing gear tooth-sizes. Module (m): m = 1 (p = 3.1416), m = 2 (p = 6.2832), m = 4 (p = 12.566). If you multiply Module by Pi, you can obtain Pitch (p). Pitch is the distance between corresponding points on adjacent teeth. |

|||

* {{Emphasis|other_teeth}}: Several pinions with the same number of teeth only can be used on one crown wheel. |

|||

==Limitations== |

|||

No limitations are known. |

|||

{{Docnav |

{{Docnav |

||

Revision as of 13:27, 9 April 2020

|

|

| Menu location |

|---|

| FCGear → Create an Crown gear |

| Workbenches |

| FCGear |

| Default shortcut |

| None |

| Introduced in version |

| v0.16 |

| See also |

| FCGear InvoluteGear |

Description

The crown wheel resembles a ring-shaped curved rack. The pressure angle decreases continuously from the outer to the inner diameter. Thus, the variable peripheral speed at the crown wheel is compensated against the constant peripheral speed of the pinion. The pointed outer teeth and the steep tooth flanks on the inner diameter limit the usable tooth width. Crown gears achieve similar efficiencies as spur gears. One crown gear can drive several pinions. Known field of application of crown gears:

- Rear axle drives for cars and motorcycles

- Swivel mechanism for operating tables

- Angular milling heads

- Powered tool systems with multiple pinions and a crown gear

Usage

- Switch to the

FCGear Workbench.

- Invoke the command several way:

- Press the

Create a Crown gear button in the tool bar.

- Using the Menu → Crown gear.

- Press the

- Change the gear parameter to the required conditions (see Properties → Data below).

Properties

Data

Base

- DataPlacement: Placement is the location and orientation of an object in space.

- DataLabel: User name of the object in the Tree view.

accuracy

- Dataconstruct: Default is True. Change to False and the construction component disappears.

- Datanum_profiles: Number of profiles used for loft.

gear_parameter

- Dataheight: Value for the gear width.

- Datamodule: Module is the ratio of the reference diameter of the gear divided by the number of teeth (see also the information in Note).

- Dataother_teeth: Number of teeth of the other gear (pinion). See also the information in Note.

- Datateeth: Number of teeth

- Datathickness: Height from the tip of tooth to the lower side of the gear ring.

involute_parameter

- Datapressure_parameter: Default is 20 (see also the information in Note).

View

The parameter descriptions of the View tab will be found in Property editor, further below at Example of the properties of a PartDesign object.

Notes

- module: Using ISO (International Organization for Standardization) guidelines, Module size is designated as the unit representing gear tooth-sizes. Module (m): m = 1 (p = 3.1416), m = 2 (p = 6.2832), m = 4 (p = 12.566). If you multiply Module by Pi, you can obtain Pitch (p). Pitch is the distance between corresponding points on adjacent teeth.

- other_teeth: Several pinions with the same number of teeth only can be used on one crown wheel.

Limitations

No limitations are known.