Tutorial KinematicAssembly

| Topic |

|---|

| Assemly3, a simple mechanism and a control panel |

| Level |

| Basic skills of Python and svg-structures are helpful |

| Time to complete |

| (I don't know yet) |

| Authors |

| FBXL5 |

| FreeCAD version |

| 0.20 and later |

| Example files |

| None |

| See also |

| None |

Introduction

This tutorial is about how to set up a simple mechanism, mainly with the tools from the external workbench Assembly3.

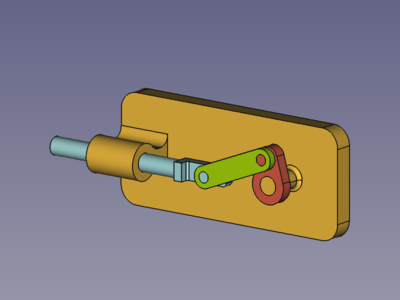

This kinematic assembly consists of four parts conencted with four joints.

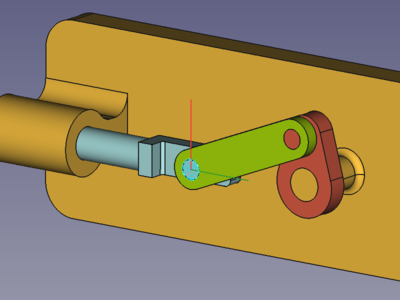

Assembled parts: Base (amber), Slider (light blue), connecting Rod (green), Crank (red)

Assembly

Parts

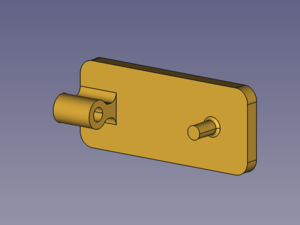

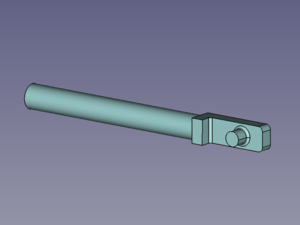

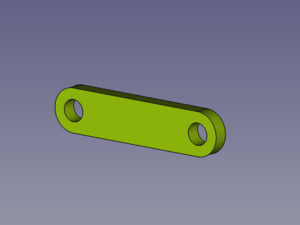

There are four parts in this assembly: Base, Slider, Crank, and connecting Rod.

The Base is an object with two main geometries, a hole and a pin. Both are cylindrical and lying perpendicular to one another. The rest of the shape is not relevant for this tutorial unless it clashes with other parts in later steps.

The Slider consists of a shaft and a pin, both cylindrical, lying perpendicular to one another. And as for the Base the rest of the shape is not relevant.

The Crank consists of a hole and a pin. Both are cylindrical and lying parallel to each other. And, guess what, the rest of the shape is not relevant, too.

The Rod consists of two cylindrical holes lying parallel to each other. And again the rest isn't relevant, as well.

Joints

Locked Base

To keep the assembly at the desired position, the base part should be locked.

- (If the

Lock mover command is activated, motion tools are deactivated as long as a locked part is selected.)

- Select one face of the Base.

- Press the button

Create "Locked" constraint to keep the Base in place permanently.

Then all four parts are connected with four joints. The kinematic chain starts at the base.

Base-to-Slider joint

The Base-to-Slider joint is a cylindrical joint. It enables the slider to slide along and spin around the Base-Hole's Z axis while keeping both elements' Z axes aligned (colinear).

The matching constraint is the "AxialAlignment" constraint. It works with elements that represent that represent cylindrical geometry such as the cylindrical face, the circular base or cover face, and circular edges.

- Select the cylindrical faces of Base hole and Slider shaft.

- Press the button

Create "AxialAlignment" constraint.

- Optionally relabel the created elements (edit their properties DataLabel).

Base-to-Crank joint

The Base-to-Crank joint is a hinge joint. It enables the Crank to spin around the Base-Hole's Z axis while keeping both elements' Z axes aligned (colinear) and the offset between their XY planes constant.

The matching constraint is the "PlaneCoincident" constraint. It works with elements that represent that represent planar geometry such as circular faces and circular edges (in this case).

- Select the circular face or edge of the Base pin and a circular edge of the Crank hole.

- Press the button

Create "PlaneCoincident" constraint.

- Optionally relabel the created elements.

Slider-to-Rod joint

The Slider-to-Rod joint is a hinge joint. It enables the Rod to spin around the Slider-Pin's Z axis while keeping both elements' Z axes aligned (colinear) and the offset between their XY planes constant.

The matching constraint is the "PlaneCoincident" constraint. (See above)

- Select the circular face or edge of the Slider pin and a circular edge of the Rod hole.

- Press the button

Create "PlaneCoincident" constraint.

- Optionally relabel the created elements.

Crank-to-Rod joint

The Crank-to-Rod joint is a cylindrical joint. It enables the slider to slide along and spin around the Base-Hole's Z axis while keeping both elements' Z axes aligned (colinear). The movement along the Z axis is already restricted through the combination of Base-to-Crank joint and Slider-to-Rod joint.

The matching constraint is the "AxialAlignment" constraint. (See above)

- Select the cylindrical faces of Crank pin and Rod hole.

- Press the button

Create "AxialAlignment" constraint.

- Optionally relabel the created elements.

Redundant Constraints

When the Base is fixed and all four joints are constrained two messages appear in the report view:

- A warning (orange): "...redundant constraints".

- A simple message (black): "...dof remaining: 0".

This combination of messages occurs when parts of an assembly are over-constrained but the solver is still able to find a valid solution. But what causes the redundacy?

It is the Z direction of the pins. If we take a look at the Slider pin for example we will notice that the Z axis of its element object is constrained parallel to the Base pin's Z axis through the assembly chain Base-Crank-Rod-Slider. This means that the Slider pin is prevented from rotating around its X and Y axes.

On the other hand the rotation around the X axis (red) is already prevented by the Base-to-Crank joint; and so the corresponding degree of freedom (dof) is constrained twice (= redundant) and causes the warning.

- To avoid this redundancy an auxilliary object and corresponding constraints could be inserted, but that is for some other tutorial.

- To avoid double constraining the offset between base and Rod, different constraints were used, with only one of them fixing the motion along the Z axis.

Actuator

Now it is still a static assembly. To turn it into a kinematic assembly one constraint has to be used as an actuator. To use the "PlaneCoincident" constraint oft the Base-to-Crank joint as an actuator, we need to control the angle between Base pin and Crank. This can be done by setting the property DataLock Angle to true. And for later use the label is marked with the suffix .Driver.

Now use the property DataAngle to spin the Crank.

Controller

To have a dialog window to change property values without typing and with automatic recomputation would be nice.

Have a look at the Kinematc Controller tutorial.