PartDesign Pad/fr: Difference between revisions

(Created page with "==Utilisation== # Sélectionner une esquisse. # Cliquer sur le bouton {{KEY|16px '''Protrusion'''}}. # Définir les paramètres de protrusion (voi...") |

(Created page with "==Options== Lors de la création de la protrusion, la vue combinée bascule automatiquement à l'onglet Tâches, qui affiche le dialogue « Paramètres de protrusion ».") |

||

| Line 15: | Line 15: | ||

==Options== |

==Options== |

||

Lors de la création de la protrusion, la vue combinée bascule automatiquement à l'onglet Tâches, qui affiche le dialogue « Paramètres de protrusion ». |

|||

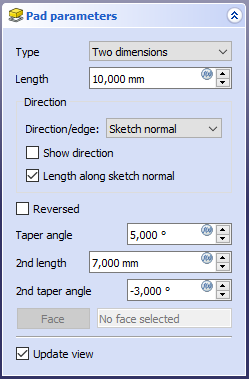

When creating a pad, the Combo view automatically switches to the Tasks pane, showing the '''Pad parameters''' dialogue. |

|||

[[Image:pad_parameters_cropped.png|frame|left]] |

[[Image:pad_parameters_cropped.png|frame|left]] |

||

Revision as of 01:47, 1 August 2014

|

|

| Emplacement du menu |

|---|

| Part Design -> Protrusion |

| Ateliers |

| Part Design, Complete |

| Raccourci par défaut |

| Aucun |

| Introduit dans la version |

| - |

| Voir aussi |

| Aucun |

Description

L'outil Protrusion crée une protrusion à partir d'une esquisse sélectionnée. Une protrusion est essentiellement l'extrusion d'un solide depuis une esquisse. Par exemple, si une esquisse a été faite de deux cercles concentriques, et que l'outil Protrusion a ensuite été utilisé sur cette esquisse, le résultat serait un tube cylindrique :

Si l'esquisse sélectionnée est appliquée sur la face d'une solide existant ou d'une autre fonction Part Design, la protrusion sera fusionnée au solide.

Utilisation

- Sélectionner une esquisse.

- Cliquer sur le bouton

Protrusion.

Protrusion. - Définir les paramètres de protrusion (voir section suivante).

- Cliquer sur OK.

Options

Lors de la création de la protrusion, la vue combinée bascule automatiquement à l'onglet Tâches, qui affiche le dialogue « Paramètres de protrusion ».

Type

Type offers five different ways of specifying the length to which the pad will be extruded.

Dimension

Enter a numeric value for the length of the pad. The default direction for extrusion is away (outside of) the support, but it can be changed by ticking the Reversed option. Extrusions occur normal to the defining sketch plane. With the option Symmetric to plane the pad will extend half of the given length to either side of the sketch plane. Negative dimensions are not possible. Use the Reversed option instead.

Two dimensions

This allows to enter a second length in which the pad should extend in the opposite direction (into the support). Again can be changed by ticking the Reversed option.

To last

The pad will extrude up to the last face of the support in the extrusion direction. If there is no support, an error message will appear.

To first

The pad will extrude up to the first face of the support in the extrusion direction. If there is no support, an error message will appear.

Up to face

The pad will extrude up to a face in the support that can be chosen by clicking on it. If there is no support, no selections will be accepted.

Length

Defines the length of the pad. Multiple units can be used independently of the user's units preferences (m, cm, mm, nm, ft or ', in or ").

Symmetric to plane

Tick the checkbox to extend half of the given length to either side of the sketch plane.

Reversed

Reverses the direction of the pad.

Limitations

- Like all Part Design features, Pad creates a solid, thus the sketch must include a closed profile or it will fail. There can be multiple enclosed profiles inside a larger one, provided none intersect each other (for example, a rectangle with two circles inside it).

- The algorithm used for To First and To Last is:

- Create a line through the centre of gravity of the sketch

- Find all faces of the support cut by this line

- Choose the face where the intersection point is nearest/furthest from the sketch

- This means that the face that is found might not always be what you expected. If you run into this problem, use the Up to face type instead, and pick the face you want.

- For the very special case of extrusion to a concave surface, where the sketch is larger than this surface, extrusion will fail. This is a unresolved bug.

- There is no automatic cleanup, e.g. of adjacent planar surfaces into a single surface. You can fix this manually in the Part workbench with Refine shape (which creates an unlinked, non-parametric solid) or with the "Refine shape feature" (which creates a parametric feature) from the OpenSCAD Workbench.