Fasteners Workbench

Introduction

The Fasteners Workbench is an external workbench that can add various fasteners to parts.

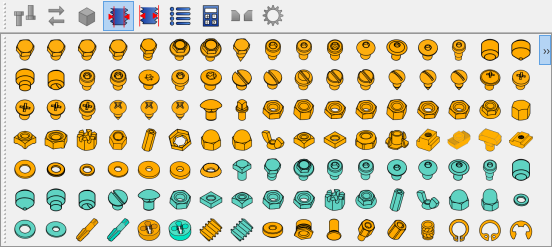

The optional single toolbar layout of the workbench.

Fasteners with metric dimensions have orange icons.

Fasteners with inch dimensions have green icons.

Installation

- Install the Fasteners Workbench via the

Addon Manager. For manual installation see Installing more workbenches.

- Restart FreeCAD.

- Select the

Fasteners Workbench from the Workbench dropdown list.

- Optionally change the toolbar and menu layout:

- Go to: Edit → Preferences... → Fasteners → General settings.

- Select one of the available Toolbar screw icons grouping options:

- None: All fasteners appear in a single toolbar. To see all available buttons use the >> button to expand it.

- Separate toolbars: Fasteners are grouped in several toolbars. This is the default layout.

- Dropdown buttons: Fasteners are grouped in toolbars with flyouts.

- Optionally uncheck one or more Fastener standards shown in toolbars options. Unchecked standards are still available from the menu.

- Restart FreeCAD.

Usage

Fasteners can be attached or unattached. Attached fasteners have a Database Object, a circular edge, and their DataPlacement is dynamically linked to that object. The Fasteners Move command can be used to attach or detach a fastener.

Unattached fasteners

- Select the desired fastener by clicking its button or by picking it from the menu.

- A fastener is created at the origin.

- Optionally change the dimensions and other properties of the fastener:

- Select the fastener.

- Go to the Data tab of the Property editor.

- Change the required properties.

Attached fasteners

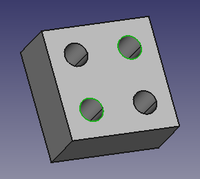

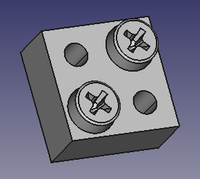

On the left two selected circular edges. On the right the attached fasteners.

- Specify if the selected holes are tap holes or pass holes by selecting

Fasteners MatchTypeInner or

Fasteners MatchTypeOuter respectively (not used for countersunk screws).

- Select one or more circular edges and/or faces with circular edges. For countersunk screws the top edge of the chamfered hole must be selected.

- Select the desired fastener by clicking its button or by picking it from the menu.

- A fastener is attached to each of the selected circular edges.

- The default dimensions of each fastener depend on the radius of the circular edge it is attached to. Countersunk screws are matched by their head diameter, other fasteners are matched by their shaft diameter.

- Optionally change the dimensions and other properties of the fasteners. See above.

- Fasteners that appear upside-down can be inverted with the

Fasteners Flip command or by changing their Datainvert property.

- Optionally change the Dataoffset property to create space between the fasteners and the edges they are attached to.

Notes

- To generate threads, the Datathread property of a fastener must be changed to

true. Generating threads is costly. Recomputes take much longer if there are many fasteners with threads in a document. - The Datainvert property and the Dataoffset property are ignored for unattached fasteners.

Commands

Invert fastener: Invert the orientation of attached fasteners.

Move fastener: Move and attach a fastener to a circular edge. Can also be used to detach a fastener.

Simplify shape: Create non-parametric copies of fasteners.

Match for tap hole: Consider circular edges to be tap holes when new fasteners are attached to them.

Match for pass hole: Consider circular edges to be pass holes when new fasteners are attached to them.

Generate BOM: Create a spreadsheet with a bill of materials for the fasteners in the document.

Screw calculator: Show a calculator to determine the tap hole size of screws.

Make countersunk: Chamfer holes for countersunk screws.

Change fastener parameters: Change the parameters of fasteners.

Fasteners

Fasteners with metric dimensions have orange icons. Fasteners with inch dimensions have green icons.

Self-clinching and PCB fasteners

Hexagon head screws and bolts

Hexagon socket screws

Hexalobular socket head screws

Slotted head screws

H cross head screws

Other head bolts

Nuts

T-slot fasteners

Washers

Retaining rings

Miscellaneous

References

- Author: shaise

- ScrewMaker: Ulrich Brammer

- Workbench wrapper: Shai Seger

- Home page: http://theseger.com/projects/2015/06/fasteners-workbench-for-freecad/

- Source code: https://github.com/shaise/FreeCAD_FastenersWB

- Bug reports and feature requests: https://github.com/shaise/FreeCAD_FastenersWB/issues

- Forum topic: https://forum.freecadweb.org/viewtopic.php?t=11429

Links

- Generating holes for countersunk screws in freecad

- BOLTS: An open library for technical specifications.

- External workbenches

- Macros recipes

- Getting started

- Installation: Download, Windows, Linux, Mac, Additional components, Docker, AppImage, Ubuntu Snap

- Basics: About FreeCAD, Interface, Mouse navigation, Selection methods, Object name, Preferences, Workbenches, Document structure, Properties, Help FreeCAD, Donate

- Help: Tutorials, Video tutorials

- Workbenches: Std Base, Arch, Assembly, CAM, Draft, FEM, Inspection, Mesh, OpenSCAD, Part, PartDesign, Points, Reverse Engineering, Robot, Sketcher, Spreadsheet, Surface, TechDraw, Test Framework

- Hubs: User hub, Power users hub, Developer hub