Translations:SheetMetal Forming/56/en

- Select the wall of the SheetMetal object to be embossed

- Select the back side of the shape defining solid

(Remember both the object to be embossed and the shape defining solid must be selected. Activate the multi-select method appropriate for your operating system: Control/Command.)

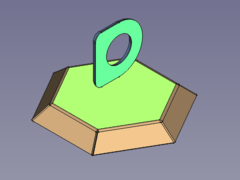

- Press the

Make Forming in Wall button

or use the keyboard shortcut: M then F

- Fillet the sharp edges:

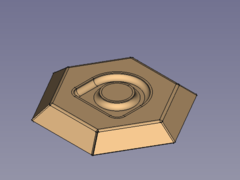

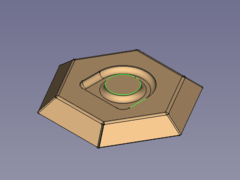

- Flip the bowl and select one or more edges for the smaller inner radii

- Press the

PartDesign Fillet button

-->

-->

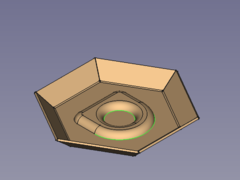

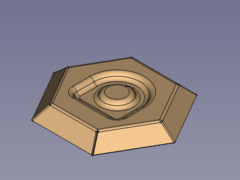

- Flip the bowl again and select one or more edges for the bigger outer radii

- Press the

PartDesign Fillet button

-->

-->

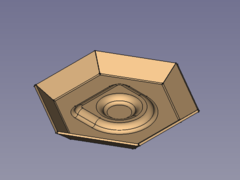

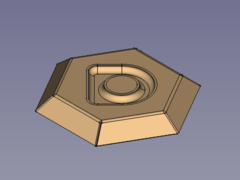

Done!

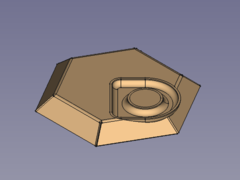

- Alter orientation and position (should be done before filleting)

- Activate the

WallForming object in the Tree view

- Set the value of the property Dataangle to e.g. 45°

- Set the value of the property Dataoffset, x to e.g. greater than 0

Here it is plain to see that it doesn't make sense to move the embossed geometry outside the selected wall.

- Setting the value of the property Dataoffset, z to e.g. greater than 0 isn't any better:

At least the FreeCAD doesn't crash when a part has two bodies...

- Activate the

- Some hints

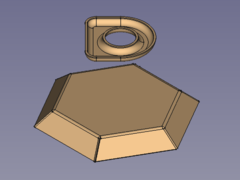

- The height of the defining solid determines the depth of the embossed shape.

That means changing the parameter offset, z to alter the depth won't deliver expected results. - The embossed geometry is made of a shell object i.e. it has a constant thickness.

And so the defining solid has to be offsetable, otherwise the tool will fail to create the emboss. - If the outer edges are filleted first it may rip the object into several pieces when the radii are set too large.

- The height of the defining solid determines the depth of the embossed shape.