Path Workbench/es: Difference between revisions

EdgarRobles (talk | contribs) No edit summary |

EdgarRobles (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

==Introducción== |

==Introducción== |

||

El banco de trabajo Trayectoria es usado para producir instrucciones maquina para[https://en.wikipedia.org/wiki/CNC_router |

El banco de trabajo Trayectoria es usado para producir instrucciones maquina para [https://en.wikipedia.org/wiki/CNC_router maquinas CNC] a partir de un modelo FreeCAD. Estos producen objetos 3D reales en maquinas CNC tales como fresadoras, tornos, cortadoras laser, o similares.Tipicamente, estas instruciones son dialeto de tipo [https://en.wikipedia.org/wiki/G-code código G]. |

||

Revision as of 22:35, 17 January 2018

Introducción

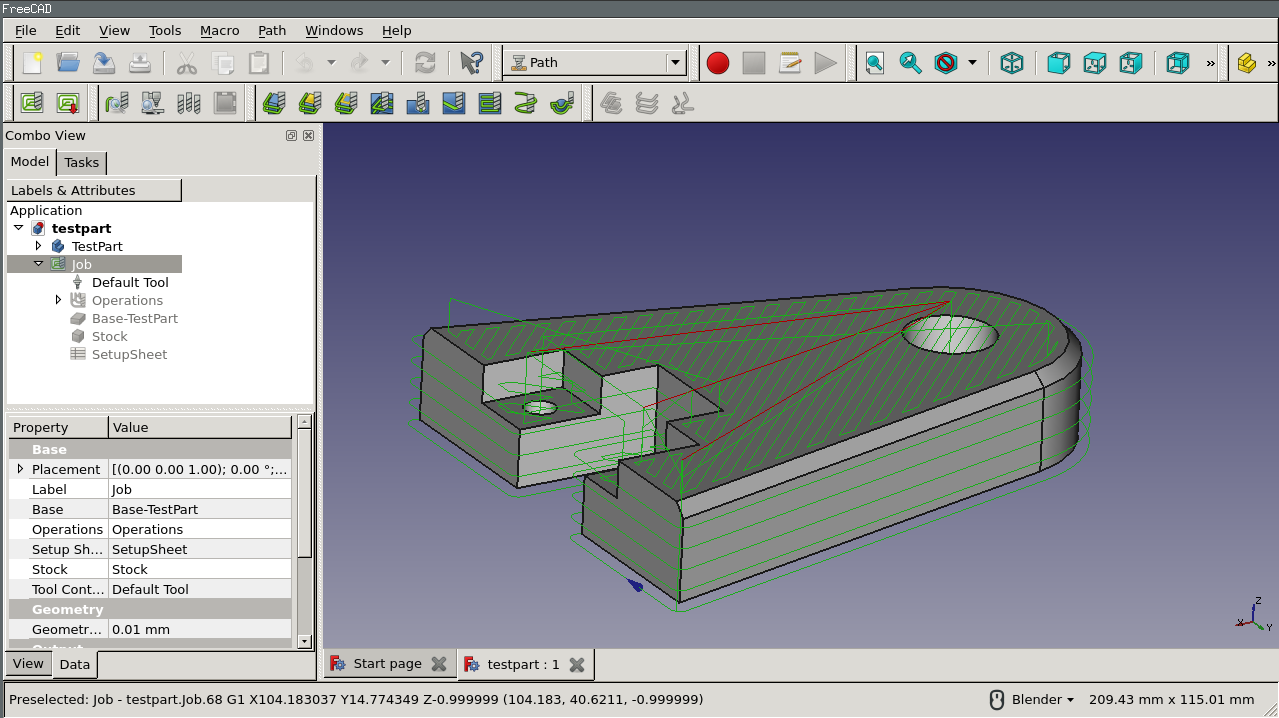

El banco de trabajo Trayectoria es usado para producir instrucciones maquina para maquinas CNC a partir de un modelo FreeCAD. Estos producen objetos 3D reales en maquinas CNC tales como fresadoras, tornos, cortadoras laser, o similares.Tipicamente, estas instruciones son dialeto de tipo código G.

La primera herramienta del banco de trabajo trayectoria es el objeto trayectoria. Un objeto trayectoria describe el movimiento que una cabeza de maquina debe ejecutar para cortar a través de un bloque de material, dentro del gabinete de la maquinas CNCs, o agregar material una capa de material imprimible, dentro del gabinete de la impresora 3D. Los objetos trayectoria pueden contener no solo información de movimiento, sino también otras instrucciones para la maquina, tal como la velocidad de rotación que el cortador debe tener, o la cantidad de material que debe usado.

Links for the impatient

Depending on your interest in the Path workbench there are different topics for further reading:

- If you are a new new user trying to get familiar with Path, you might be interested in a fast walk-through tutorial.

- If you have a special machine which cannot use one of the available postprocessors you may want to write your own postprocessor

- As an experienced user you may want to write a macro for the Path Workbench

- Power users may want to streamline processes.

- New Developers might want to understand core concepts.

General concepts

The Path Workbench generates the G-Code defining the paths required to mill the Project represented by the 3D model on the destination mill—in a simple agnostic G-Code dialect which is later translated to the appropriate dialect for the target CNC controller by selecting the proper Postprocessor.

The G-Code is generated from directives and Operations contained in a Path Job. The Job Workflow lists these in the order they will be executed. The list is populated by adding Path Operations, Path Dressups, Path Partial Commands, and Path Modifications—from the Path Menu, or GUI buttons.

A summary of the contents of the Path Job includes:

- A list of Tool-Controller definitions, specifying the geometry, Feeds, and Speeds for the Path Operations Tools.

- A Workflow sequential list of Path Operations.

- A Base Body—a clone used for offset.

- A Stock, representing the raw material that will be milled to Path Workbench.

- A SetupSheet, containing inputs used by the Path Operations, including static values and formulas.

- Configuration parameters specifying the output G-Code job's destination path, file name, and extension, and the Postprocessor—used to generate the appropriate dialect for the target CNC Controller, and customize Units, Tool Changes, Parking, etc...

The Path Workbench provides a Tool Manager (Library, Table), and G-Code Inspection, and Simulation tools. It links the Postprocessor, and allows importing and exporting Job Templates.

The Path Workbench has external dependencies including:

- The FreeCAD 3D model units are defined in the Edit-> Preference...->General->Units tab's Units settings. The Postprocessor configuration defines the final G-Code units.

- The Macro file path, and Geometric tolerances, are defined in the Edit->Preferences...->Path->Job Preferences tab.

- Colors are defined in the Edit->Preferences...->Path->Path colors tab.

- Holding tag parameters are defined in the Edit->Preferences...->Path->Dressups tab.

- That the Base 3D model quality supports the Path WB requirements—passes Check Geometry.

FreeCAD Path Workbench internal G-Code dialect represents Feed rates in Units/Second—what the G-Code Inspection tool will show. The Postprocessor is configured to generate the appropriate Feed rates—either in Units/Second or Units/Minute for the target mill.

Herramientas de GUI

Archivos de guión

El banco de trabajo Trayectoria ofrece un amplia API de archivos guión de python que tu puedes crear y modificar trayectorias de archivos guión de python, o extender las funciones disponibles del banco de trabajo.

Why does my operation not produce output?

Can Path Workbench perform 3D surfacing machining?

Can I modify an existing, or make my own Postprocessor?

How I can set metric/imperial to my path object?

How I can simulate my strategies?

El banco de trabajo Trayectoria todavía esta en estados tempranos de desarrollo.Algunas de las herramientas debajo tal ves no funcionan como se espera.}}