Path Workbench

Introduction

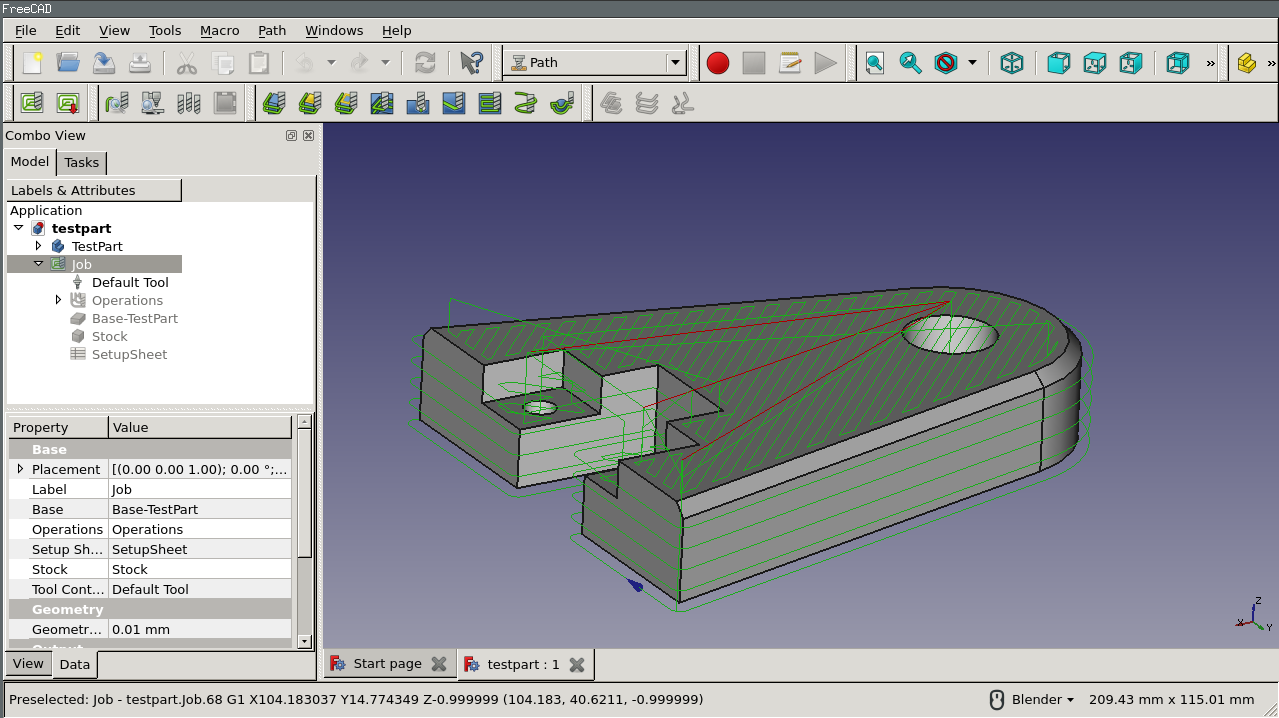

The Path workbench is used to produce machine instructions for CNC machines from a FreeCAD model. These produce real-world 3D objects on CNC machines such as mills, lathes, lasercutters, or similar. Typically, these instructions are some kind of G-Code dialect.

The FreeCAD Path Workbench workflow creates these machine instructions as follows:

- A 3D model is the base object, typically created using one or more of the Part Design, Part or Draft Workbenches.

- A Job is created in Path Workbench. This contains all the information required to generate the necessary G-Code to process the Job on a CNC mill: there is Stock material, the mill has a certain set of tools and it follows certain commands controlling speed and movements (usually G-Code).

- Tools are selected as required by the Job Operations.

- Milling paths are created using e.g. Contour and Pocket Operations. These Path objects use an internal agnostic FreeCAD G-Code dialect which is independent of the CNC machine.

- Because each CNC Controller speaks a specific G-Code dialect, a Dialect-correct Postprocessor translates from the internal agnostic FreeCAD G-Code. Several Postprocessors are included allowing direct use or as a templates for modification. Postprocessors contain configuration flags and are designed to be tuned by adding G-Codes and M-Codes to provided definitions for:

- Machine initialization

- Job finalization

- Tool-Changes

- Cooling on /off

- Etc...

Links for the impatient

Depending on your interest in the Path workbench there are different topics for further reading:

- If you are a new new user trying to get familiar with Path, you might be interested in a fast walk-through tutorial.

- If you have a special machine which cannot use one of the available postprocessors you may want to write your own postprocessor

- As an experienced user you may want to write a macro for the Path Workbench

- Power users may want to streamline processes.

- New Developers might want to understand core concepts.

General concepts

The Path Workbench generates G-Code defining the paths required to mill the Project represented by the 3D model on the target mill—in a simple agnostic G-Code dialect which is later translated to the appropriate dialect for the target CNC controller by selecting the appropriate Postprocessor.

The G-Code is generated from directives and Operations contained in a Path Job. The Job Workflow lists these in the order they will be executed. The list is populated by adding Path Operations, Path Dressups, Path Partial Commands, and Path Modifications—from the Path Menu, or GUI buttons.

A summary of the contents of the Path Job includes:

- A list of Tool-Controller definitions, specifying the geometry, Feeds, and Speeds for the Path Operations Tools.

- A Workflow sequential list of Path Operations.

- A Base Body—a clone used for offset.

- A Stock, representing the raw material that will be milled to Path Workbench.

- A SetupSheet, containing inputs used by the Path Operations, including static values and formulas.

- Configuration parameters specifying the output G-Code job's destination path, file name, and extension, and the Postprocessor—used to generate the appropriate dialect for the target CNC Controller, and customize Units, Tool Changes, Parking, etc...

The Path Workbench provides a Tool Manager (Library, Tool-Table), and G-Code Inspection, and Simulation tools. It links the Postprocessor, and allows importing and exporting Job Templates.

The Path Workbench has external dependencies including:

- The FreeCAD 3D model units are defined in the Edit-> Preference...->General->Units tab's Units settings. The Postprocessor configuration defines the final G-Code units.

- The Macro file path, and Geometric tolerances, are defined in the Edit->Preferences...->Path->Job Preferences tab.

- Colors are defined in the Edit->Preferences...->Path->Path colors tab.

- Holding tag parameters are defined in the Edit->Preferences...->Path->Dressups tab.

- That the Base 3D model quality supports the Path WB requirements—passes Check Geometry.

FreeCAD Path Workbench internal G-Code dialect represents Feed rates in Units/Second—what the G-Code Inspection tool will show. The Postprocessor is configured to generate the appropriate Feed rates—either in Units/Second or Units/Minute for the target mill.

GUI tools

Scripting

The Path workbench offers a broad python scripting API. With it, you can create and modify paths from python scripts, or extend the available functionality of the workbench.

FAQ

How many axes can Path Workbench handle?

At the moment Path Workbench can handle up to 3 axis milling.

What is the difference between Clearance Height and Safe Height?

More detailed information is available in depths and heights.

File:FreeCAD Path-DepthsAndHeights.png

What is the typical use of the SetupSheet?

The SetupSheet is a dedicated spreadsheet contained within a Job, modified in the Property view, accessible only from Path workbench. It provides a mechanism for more expert users to configure aspects of their Job by using Values and Expressions contained within the SetupSheet.

Current inputs for Depths, Heights, and Tool Controllers include:

- Final Depth Expression -- OpFinalDepth

- Start Depth Expression -- OpStartDepth

- Step Down Expression -- Defaults to OpToolDiameter. This expression is used for each Operation to calculate its default Step down value based on the diameter of the Tool defined in the associated Tool controller.

- Clearance Height Expression -- StartDepth+SetupSheet.ClearanceHeightOffset

- Clearance Height Offset Value -- Contains value used in Expressions

- Safe Height Expression -- StartDepth+SetupSheet.SafeHeightOffset

- Safe Height Offset Value -- Contains value used in Expressions

- Horizontal Rapid Value -- Provides the default value used to initially populate the Horizontal Rapid Feed rate for all Tool controllers.

- Vertical Rapid Value -- Provides the default value used to initially populate the Vertical Rapid Feed rate for all Tool controllers.

This provides flexibility. For example, default expressions are provided, but can be overwritten by the user. The modification can even reduce the default equation to a Value if that suits the user.

What is the typical use of the Job Templates?

Job templates provide a mechanism for saving commonly used Job definitions from an existing Job, then importing them when creating future similar Jobs to save setup time.

Available definition data that can be exported/imported includes:

- Postprocessor

- Extent and Placement of the Stock

- Operation Depths, Heights, and Tool Controller data contained in the SetupSheet

- Tool Controllers

Exporting a template can be done at any time, from within the Path workbench Job, using the Path->Export Template menu, or by right clicking the Job in the Combo View.

How many Base objects does Path workbench support?

Support exists only for a single Base object. To create paths for multiple solids in a single Job you can make a Compound out of them and use that as the base object for the Job.

Why does an Operation not produce usable output?

A variety of reasons exist that may cause an individual Operation to generate no output.

A common reason is that the Tool geometry defined in the Tool controller selected for the Operation is too large to fit within the geometry selected on the 3D model for the Operation.

Be aware that this will typically exhibit as a Rapids movement to where the Operation beginning, completed by a Rapid Z movement to the geometry selected to define the Operation, and then a return to Rapid transit height.

Can Path Workbench perform 3D surface milling?

Yes, Path provides for 3D surface milling Operations. It requires installation in the Macro file path of OpenCamLibrary--a 3rd party Open Source module.

Can I modify an existing, or make my own Postprocessor?

Postprocessors are Python scripts, and are saved in the Macro file path.

The provided Postprocessors are written with comments indicating sections containing Flags, Configuration Variables, and Sections of G-Codes and M-Codes that are to be used by the Postprocessor to configure the output.

Typical Configuration True/False Flags include:

- OUTPUT_COMMENTS (True = Allow, False = Suppress)

- OUTPUT_HEADER (True = Allow, False = Suppress)

- OUTPUT_LINE_NUMBERS (True = Allow, False = Suppress)

- SHOW_EDITOR (True = Allow, False = Suppress)

- MODAL (True = Allow, False = Suppress)

Typical Configuration Variables include:

- LINENR (Line Number Offset)

- UNITS (G20 or G21)

- MACHINE_NAME (Name of Target CNC Mill)

- PRECISION (Number of digits after the decimal place in final output file)

Typical Configuration Sections include:

- PREAMBLE (Code configuration inserted at beginning of the Job)

- POSTAMBLE (Code configuration appended to the Job, providing for parking the machine, etc...)

- TOOL_CHANGE (Code inserted with each tool change in the Job)

How I can set metric/imperial units for my path object?

The 3D model units are defined in the Edit->Preferences...>General->Units tab's User System drop menu.

The Units setting configuring how the the target mill interprets the Job G-Code is set in the output Postprocessor, which inserts a G20, or a G21 G-Code command to indicate inches or millimeters, respectively.

The Postprocessor also is configured for Units/Second, or Units/Minute. If set for Units/Minute, the Path workbench internal G-Code dialect Feed rate is multiplied by 60.

Mismatches between the 3D model and Postprocessor settings are likely culprits for factor of 60 errors in Feed rate, and factors of 25.4 in distance.

How I can simulate my strategies?

A volumetric simulator is provided to view the result of cutting the tool geometries included in the Job Operations against the Stock.

What is the significance of path line colors?

Path line colors are defined in the Edit->Preference...->Path->Path colors tab. Default colors include:

- Green for normal paths.

- Red for rapid paths.

- Yellow for Probed paths.

How do I check that my G-Code sequence is correct?

By default, the Postprocessor output is displayed in a window before saving. This--along with the Path CAM simulator provide a means to examine the Job before processing it on a CNC machine. The G-Code inspection tool allows you to inspect the internal Path G-Code for each Operation, providing a means to trace whether the output of the Postprocessor reflects what is defined in the Operation.

The Operations list in the Combo View panel displays the sequence that the operations will be processed in the Job. If the Operations are correct, but not in the desired sequence, that can be adjusted by double clicking the Operations list and dragging the Operations to their proper location, or by double clicking the Job editor and selecting the Workflow tab, then using the Up/Down arrows on selected Operations to sort them.

Why is Path workbench missing functionality on my computer that I see in other users forum posts?

By default, certain expert or developmental functionality is hidden in Path workbench. To change this requires the user edit their

'Tools'->'Edit Parameters...' to create a new Boolean parameter BaseApp.Preferences.Mod.Path.EnableExperimentalFeatures, set to True.

Path_wb_enable_experimental_features.PNG