SheetMetal AddJunction: Difference between revisions

(added pictures) |

(Updated notes to match SheetMetal_AddBend.) |

||

| Line 56: | Line 56: | ||

<!--T:8--> |

<!--T:8--> |

||

The tools [[Image:SheetMetal_AddRelief.svg|16px]] '''[[SheetMetal_AddRelief|SheetMetal AddRelief]]''', [[Image:SheetMetal_AddJunction.svg|16px]] '''SheetMetal AddJunction''', and [[Image:SheetMetal_AddBend.svg|16px]] '''[[SheetMetal_AddBend|SheetMetal AddBend]]''' work best with hollow cuboids i.e. shell objects with a constant thickness and only 90° angles between faces. |

|||

<!--T:9--> |

<!--T:9--> |

||

See |

See [[SheetMetal_AddRelief#Notes|SheetMetal AddRelief]] for hints about creating shell objects of cuboids. |

||

==Properties== <!--T:10--> |

==Properties== <!--T:10--> |

||

Revision as of 10:19, 3 October 2021

This documentation is not finished. Please help and contribute documentation.

GuiCommand model explains how commands should be documented. Browse Category:UnfinishedDocu to see more incomplete pages like this one. See Category:Command Reference for all commands.

See WikiPages to learn about editing the wiki pages, and go to Help FreeCAD to learn about other ways in which you can contribute.

|

|

| Menu location |

|---|

| SheetMetal → Make Junction |

| Workbenches |

| SheetMetal |

| Default shortcut |

| S J |

| Introduced in version |

| - |

| See also |

| None |

Description

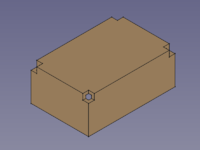

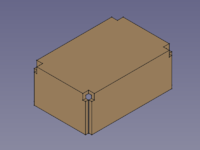

The Make Junction command starts the second of three steps to convert a shell object made with tools of the Part or PartDesign workbench into an unfoldable SheetMetal object.

As long as three faces meet at a corner and each face is joined to both other face the object can't be unfolded, and so one joint has to be cut open.

Folding a corner needs two bends; and the two remaining edges meet at a junction, thus the naming Make Junction.

- (Junction sounds odd to me. Native speakers please review)

Make Junction - cut edges open

Usage

Second step to convert a hollow cuboid (shell object) into an unfoldable SheetMetal object:

- Cut the edges open

- Select one or more edge(s)

- Activate the

Make Junction command using the:

Make Junction button

- SheetMetal →

Make Junction drop down menu

- keyboard shortcut: S then J

Notes

The tools SheetMetal AddRelief,

SheetMetal AddJunction, and

SheetMetal AddBend work best with hollow cuboids i.e. shell objects with a constant thickness and only 90° angles between faces.

See SheetMetal AddRelief for hints about creating shell objects of cuboids.

Properties

See also: Property editor.

A SheetMetal Junction object is derived from a Part Feature object and inherits all its properties. It also has the following additional properties and its label has a default value:

Data

Base

- DataLabel (

String): Default value:Junction(+ a sequential number for second and following items).

The user editable name of this object, it may be any arbitrary UTF8 string. - Data (hidden)Base Feature (

Link): Base Feature. Link to the parent feature. - Data (hidden)_Body (

LinkHidden): Hidden link to the parent body.

Parameters

- Database Object (

LinkSub): "Base Object". Links to the edges defining gap/junction positions. - Datagap (

Length): "Junction Gap". Default:2,00 mm.Size of gap/junction to be added.